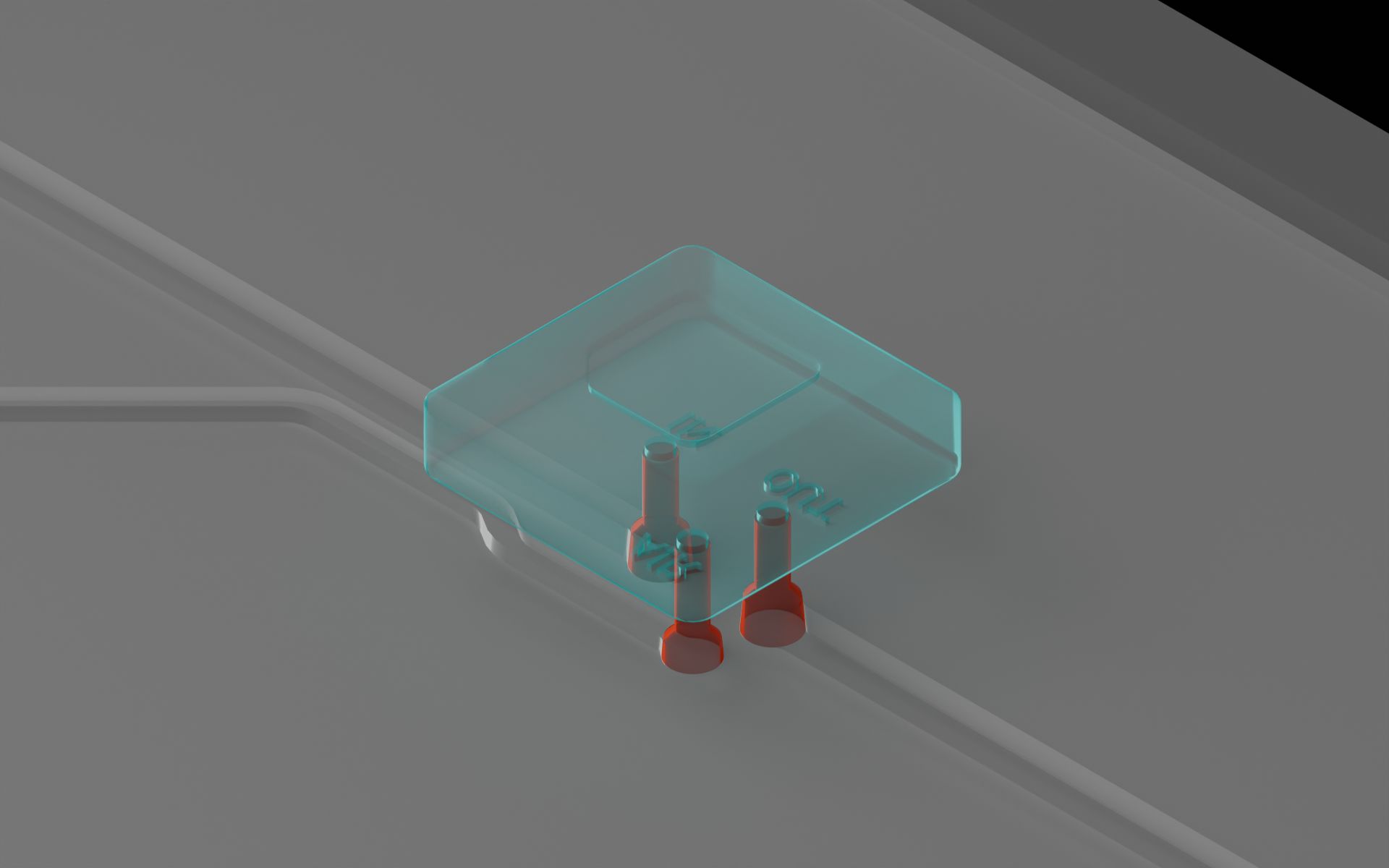

Microvalves

Part of Hardware

Part of Hardware

Control flow inside your device.

Microvalves can be built directly into your device to automatically start and stop flow. The MV-1 is designed for applications that need low dead-volume and fast switching speeds. The MV-2 is best for point-of-care and portable applications.

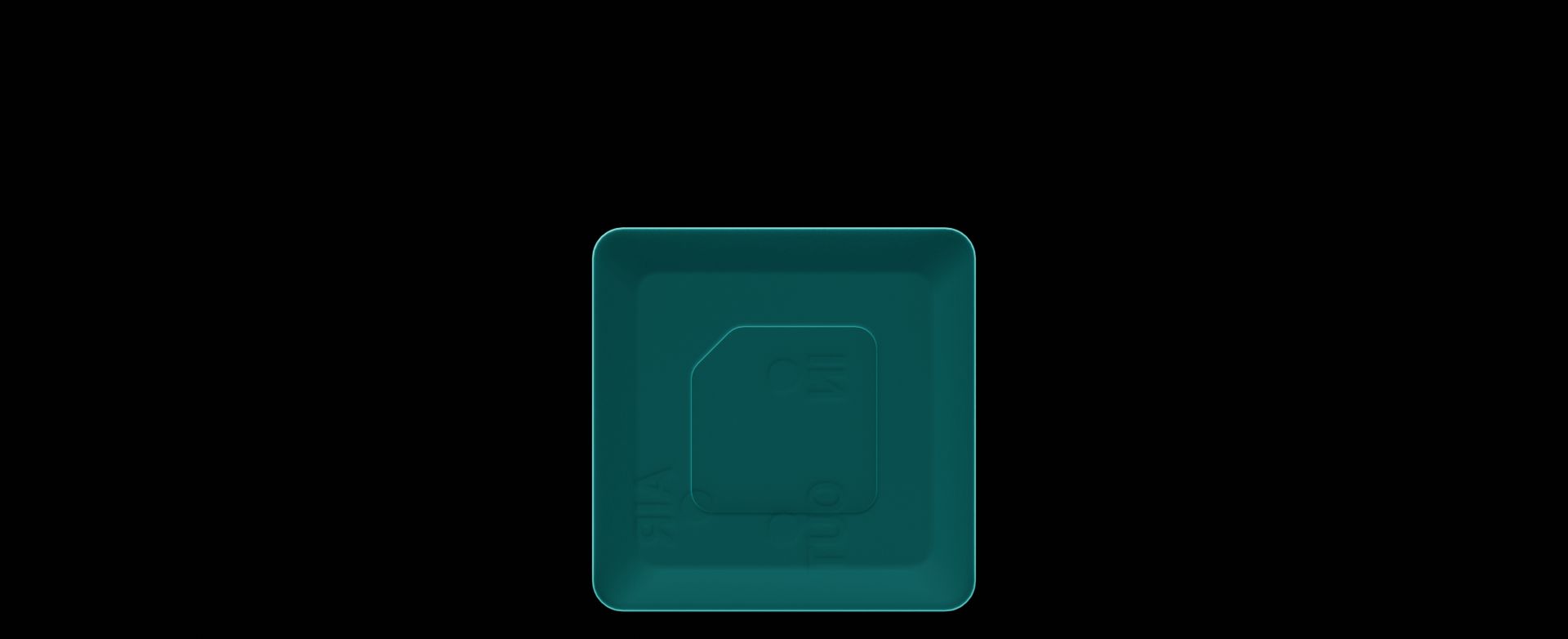

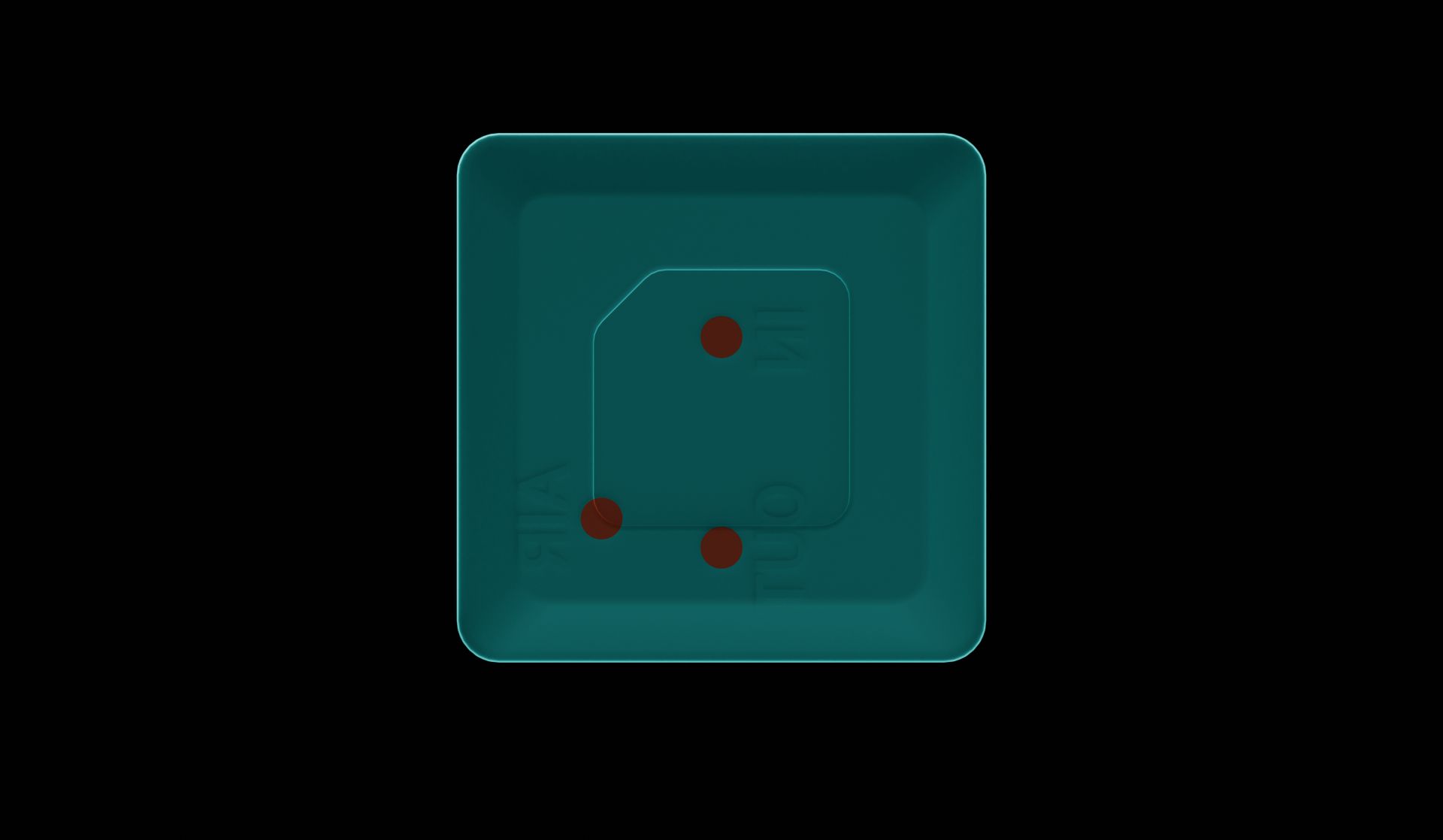

The MV-1 must have a square safe area with a side length of 4.50 mm. The safe area of any two pieces of hardware must never overlap.

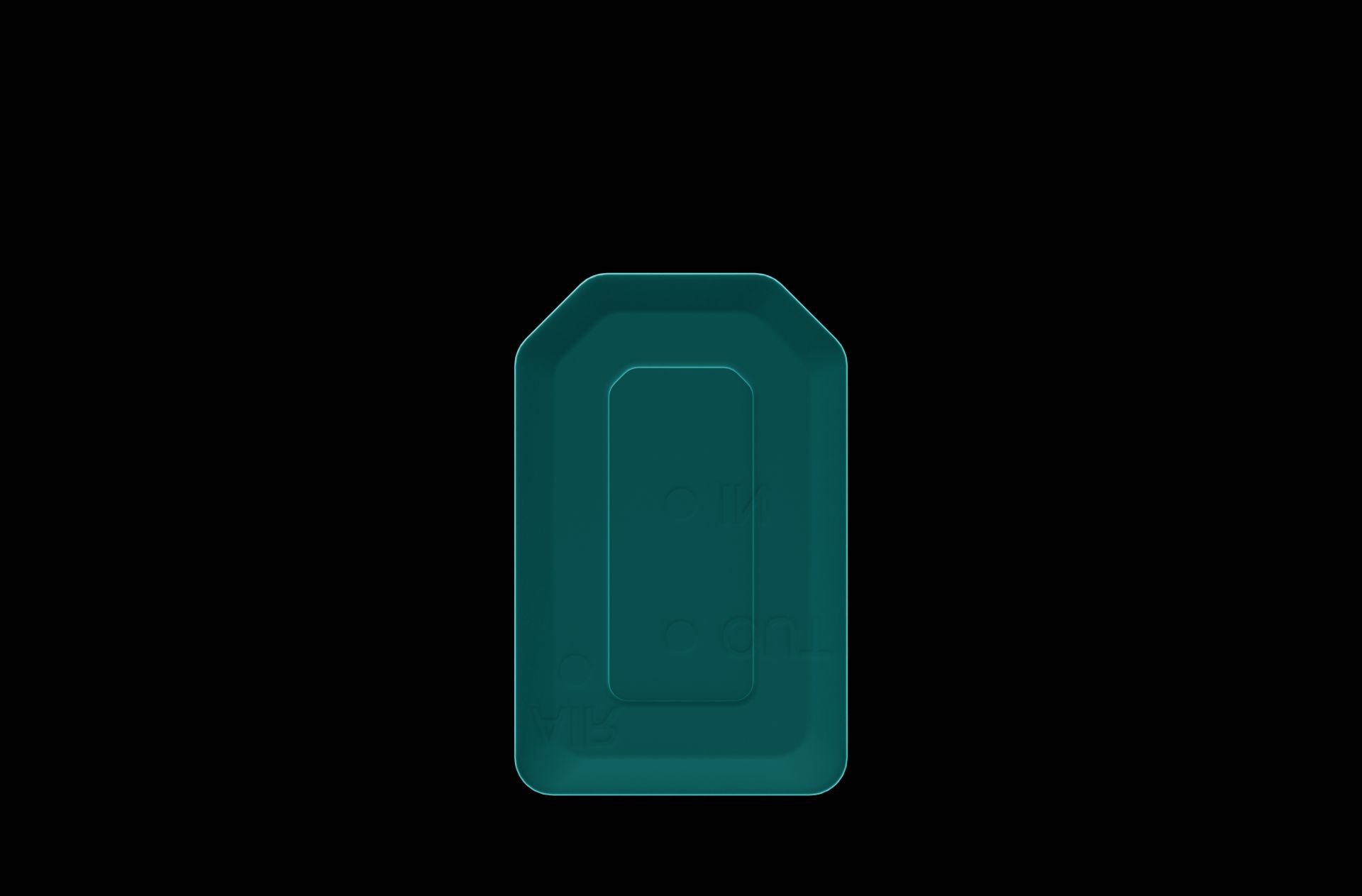

The MV-2 must have a rectangular safe area with a width of 4.50 mm and a height of 9.00 mm. The safe area of any two pieces of hardware must never overlap.

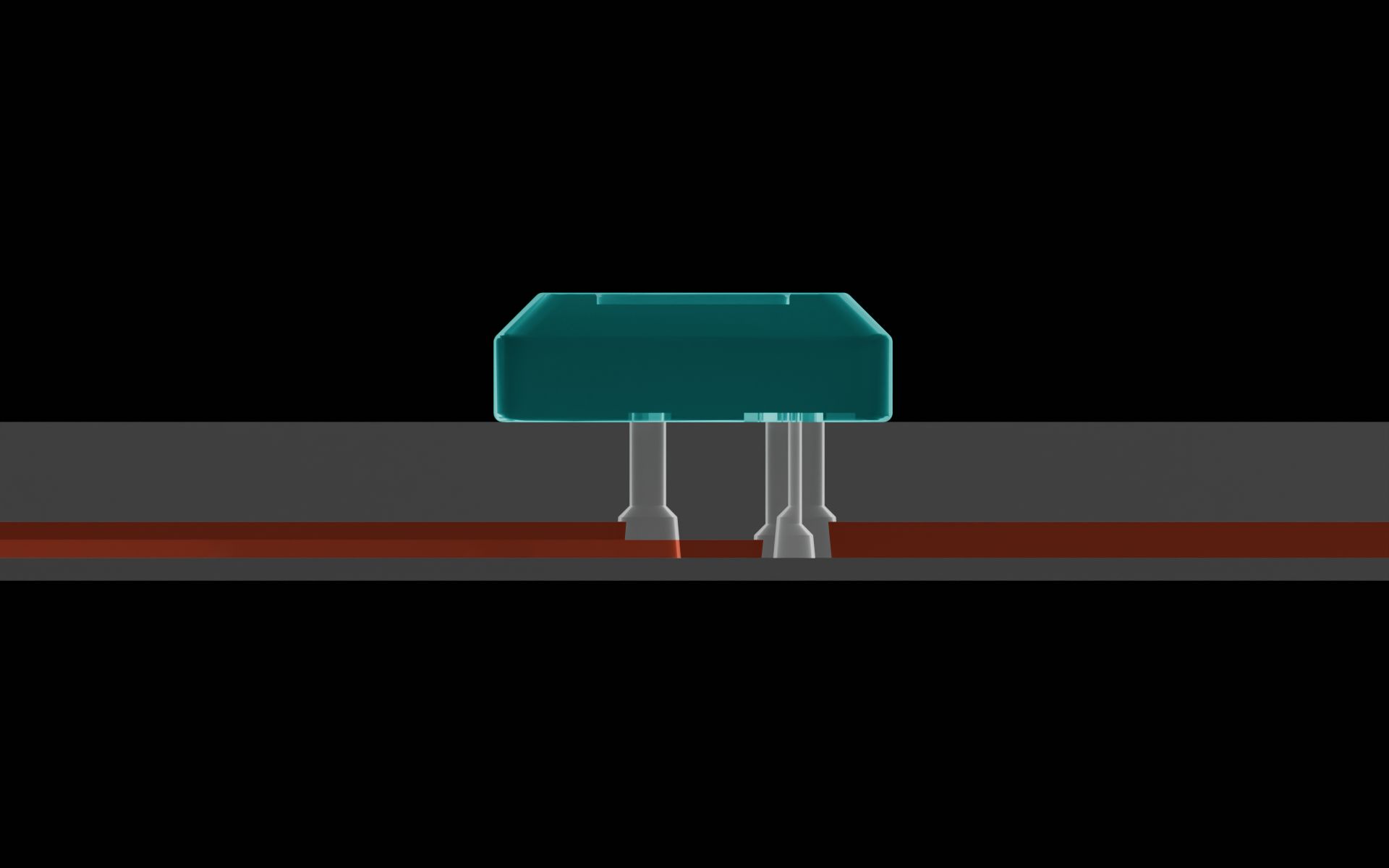

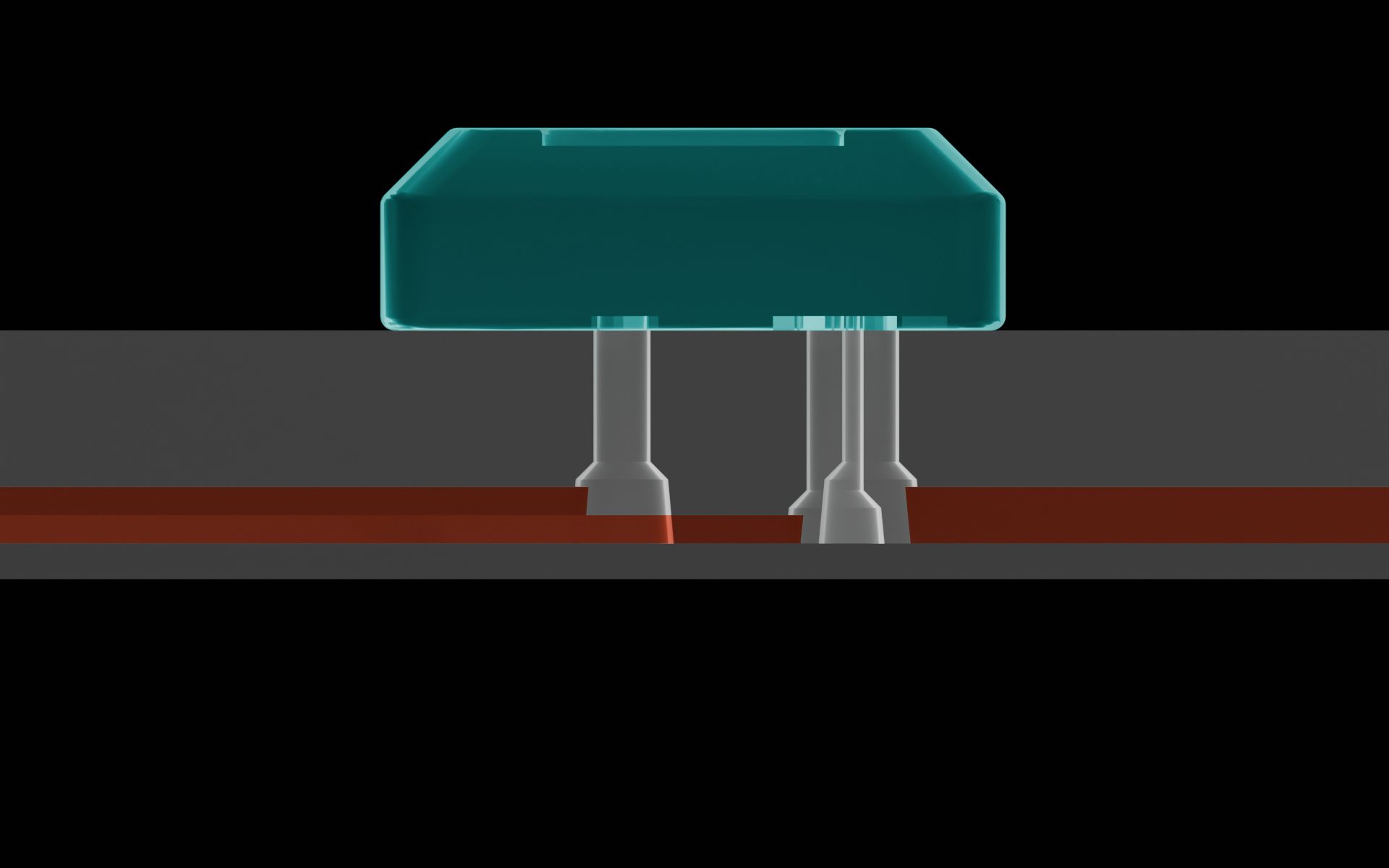

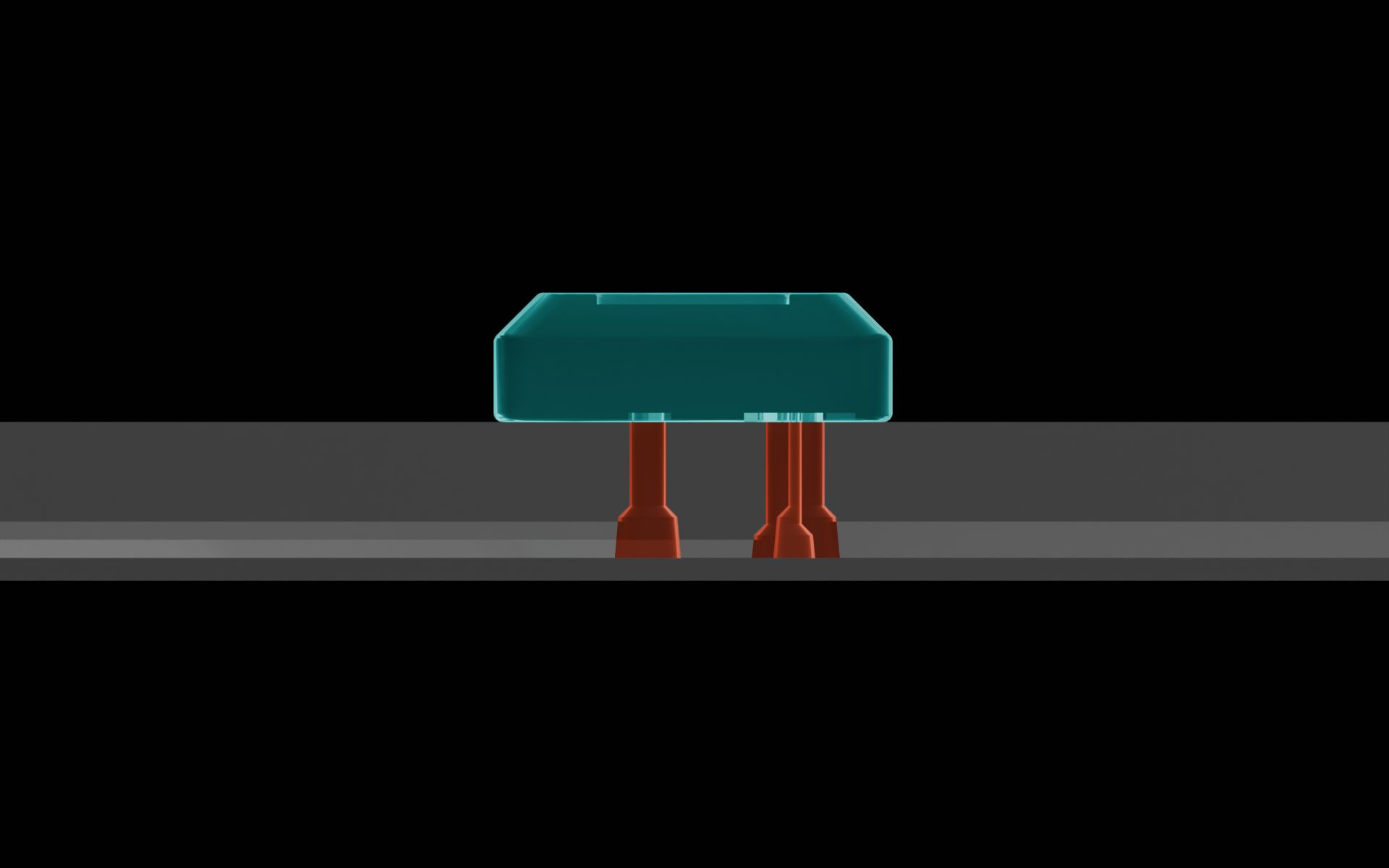

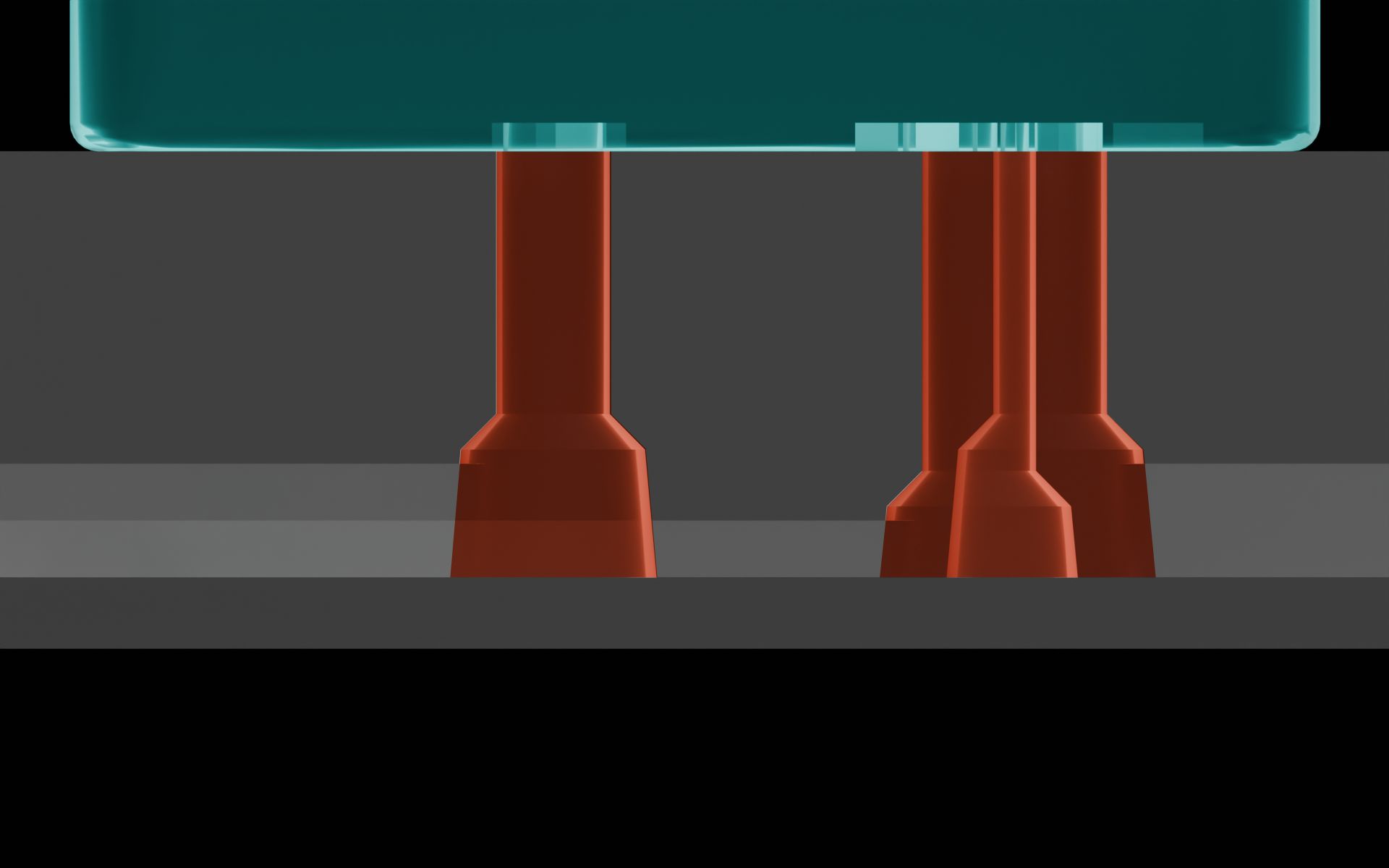

Vias connect the microvalve’s liquid inlet, liquid outlet, and air inlet to the molded microfeatures in your fluidic layer. The diameter (D) of the vias’ machined portion must be 400 μm.

Vias connecting to the MV-1 must match the liquid inlet (IN), liquid outlet (OUT), and air inlet (AIR) spacing specified below:

Vias connecting to the MV-2 must match the liquid inlet (IN), air inlet (AIR), and liquid outlet (OUT) spacing specified below:

The distance between the top surface of molded microfeatures and the base of a microvalve must be at least 1.00 mm.