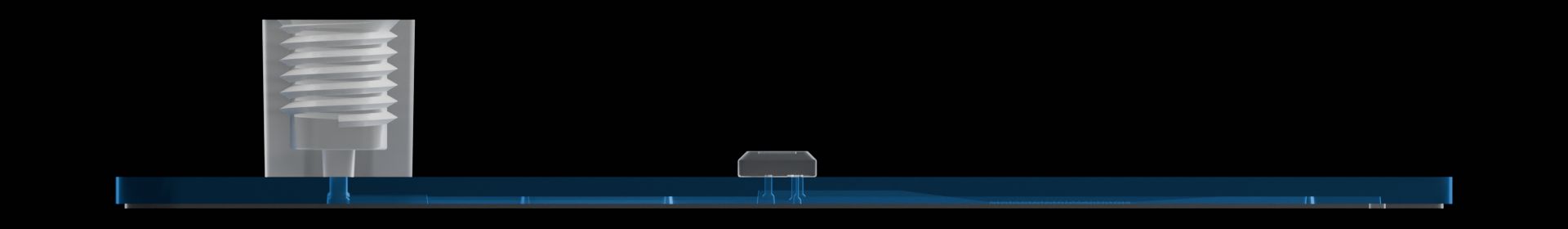

Outer Dimensions

Part of Fluidic Layer

Part of Fluidic Layer

Design a fluidic layer with a custom footprint or start from a Core Format template.

We recommend starting from a Core Format design template whenever possible to reduce cost and maximize compatibility with Transition Molding.

For custom footprints, the X-Y dimensions of a fluidic layer can be any size and shape from 10 mm x 10 mm up to 127.76 mm x 85.48 mm, the standard microplate size defined by the Society for Laboratory Automation and Screening (ANSI/SLAS 1-2004: Microplates — Footprint Dimensions).

| Dimension | Minimum | Maximum |

|---|---|---|

| Width (X) | 10.00 mm | 85.48 mm |

| Depth (Y) | 10.00 mm | 127.76 mm |

The thickness (Z) of the fluidic layer can be any dimension from 1 mm - 6 mm. We recommend 1.5 mm - 2 mm thickness to reduce cost and ensure compatibility with high-volume manufacturing.

| Dimension | Minimum | Maximum |

|---|---|---|

| Thickness (Z) | 1.00 mm | 6.00 mm |

The outer perimeter of the fluid layer should have a corner radius of 1.50 mm.