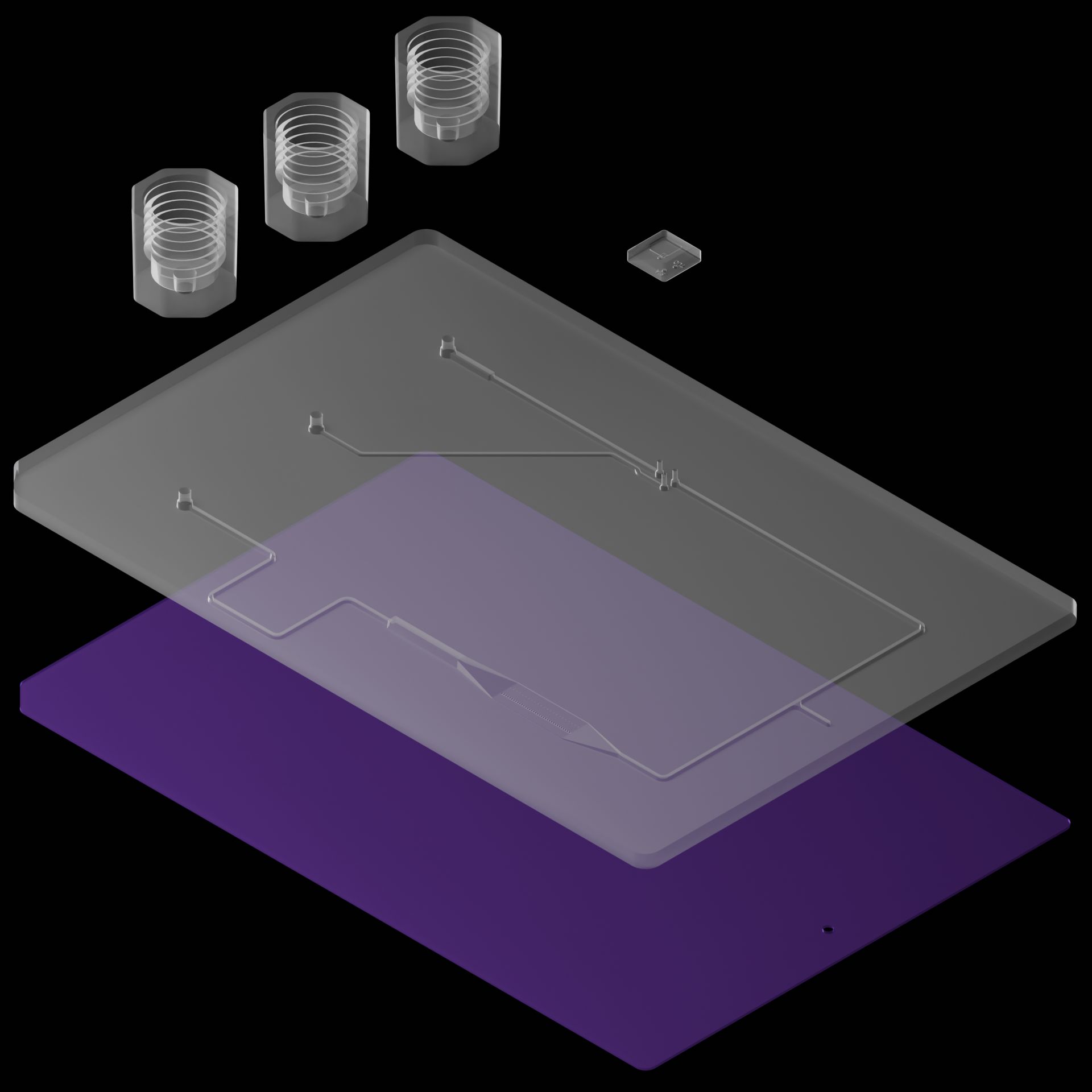

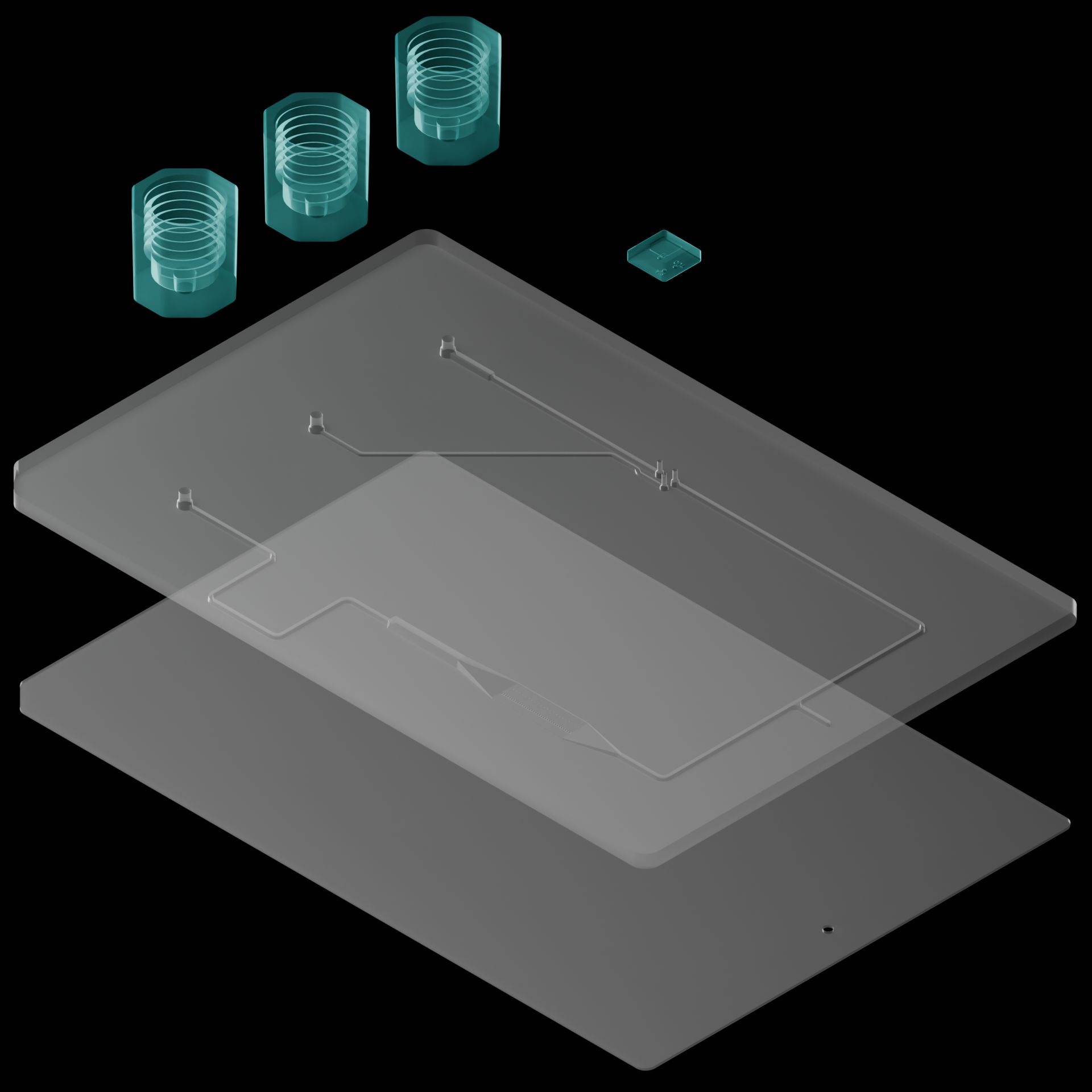

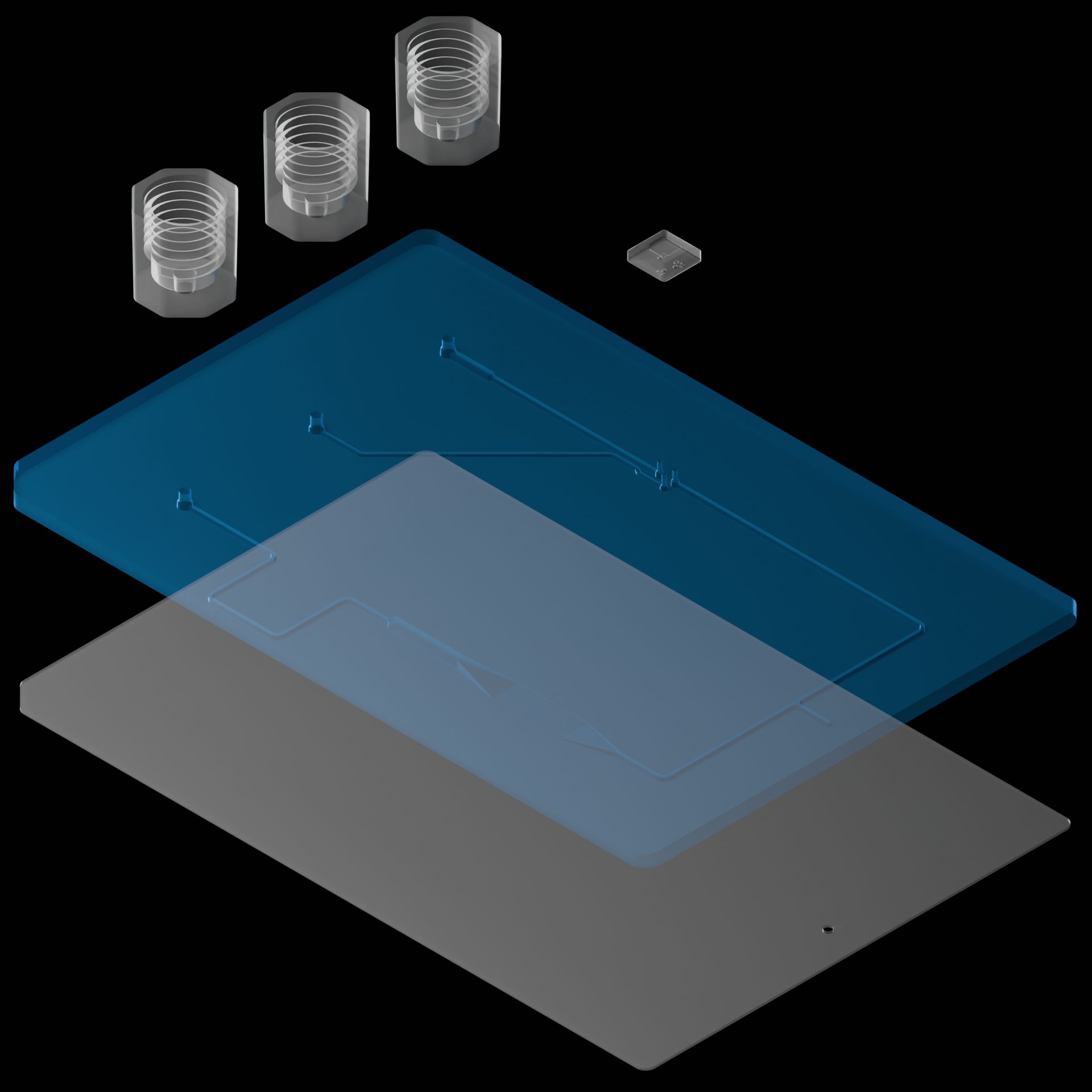

Device Architecture

Part of Get Started

Part of Get Started

Production-grade microfluidic devices from day one.

Our standard architecture combines Parallel Hardware, a customizable fluidic layer, and a thin film cap.

Parallel Hardware solves on-chip engineering challenges so you don’t have to. Explore the hardware library to learn about products like microvalves, liquid interfaces, and more. Hardware can be built directly into your prototype device or supplied in bulk when you scale up to mass manufacturing.

Your microfeatures and channels are molded into a custom fluidic layer. Transition Molding technology lets you build devices in production-grade materials from day one, eliminating the risks found in common microfluidic prototyping techniques like 3D printing or PDMS casting.

The cap is a thin, optically clear film bonded to the fluidic layer to seal your channels and microfeatures. All caps are available in the same material as your fluidic layer for maximum chemical and biology compatibility.