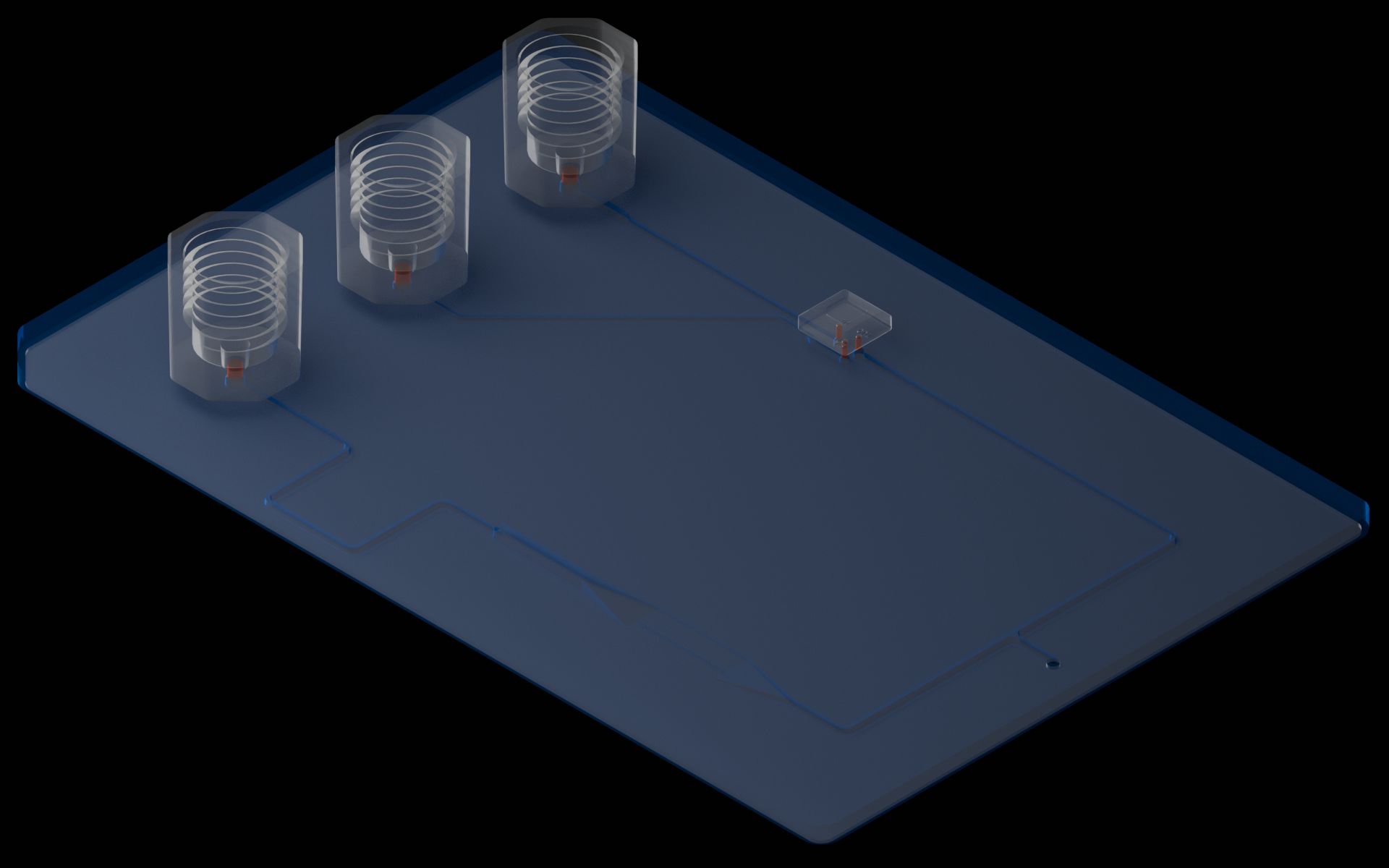

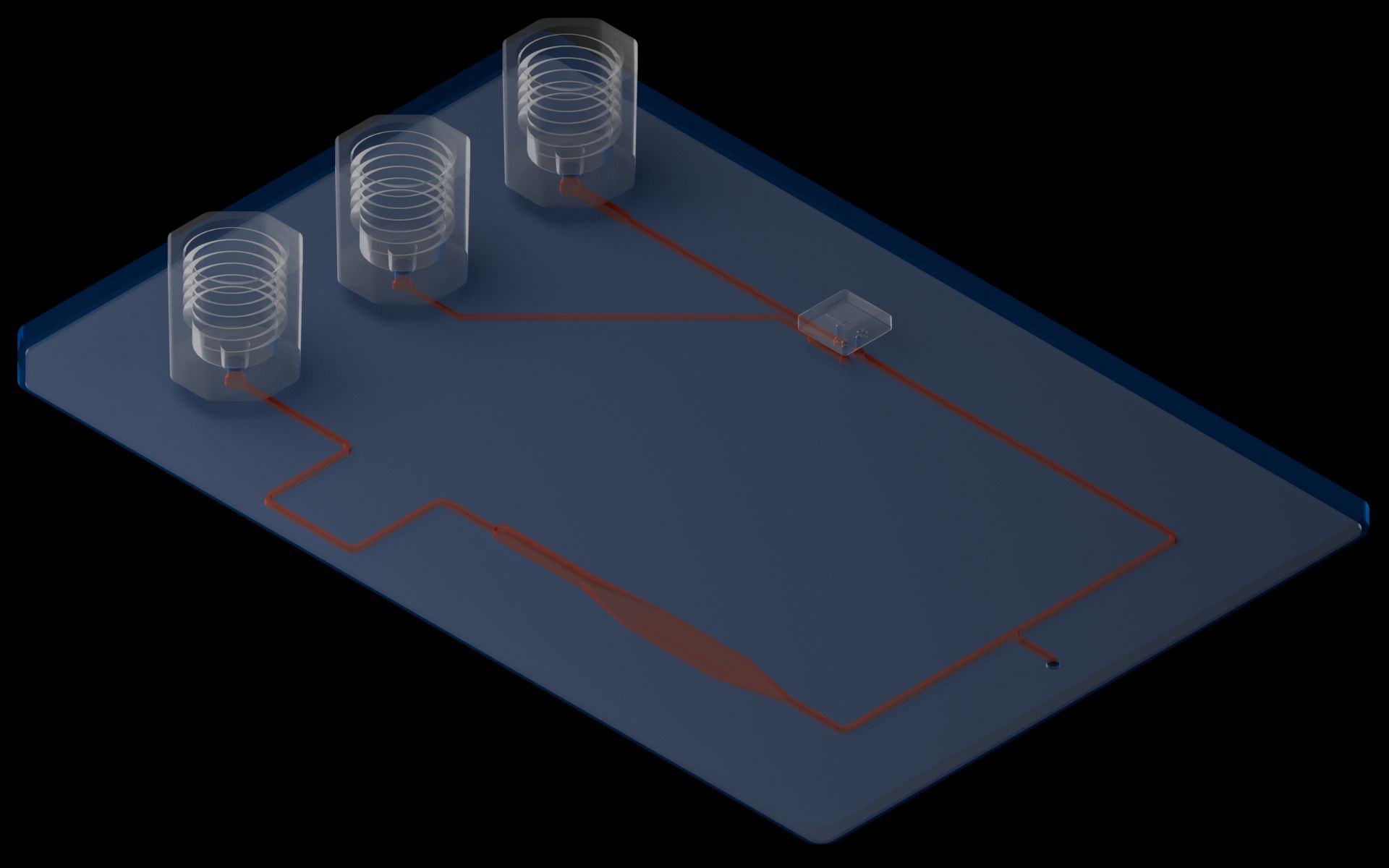

Fluidic Layer

Part of Device Architecture

Part of Device Architecture

The heart of your device with your custom microfeatures.

Following the guidelines will guarantee that your fluidic layer can be transition molded successfully.

The fluidic layer is manufactured using these steps:

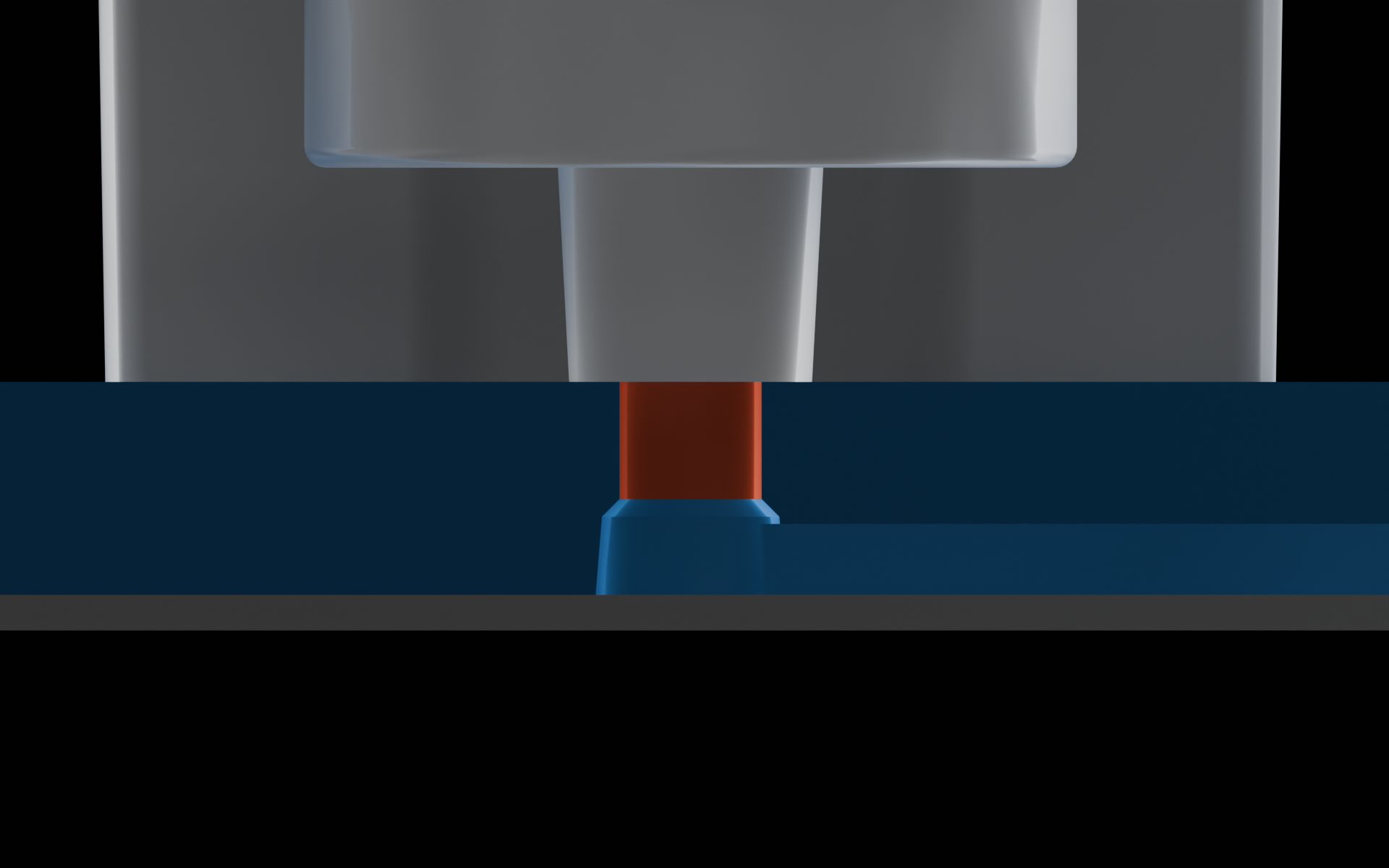

Transition Molding is a proprietary technology that allows us to manufacture custom devices in production-grade resins 10X faster than legacy techniques like micro-injection molding. The process starts by precision machining an aluminum mold that contains a negative of your custom fluidic layer. Then, the finished mold is installed into one of our Transition Molders where molten plastic is forced against the aluminum mold, creating a precise copy of your fluidic layer. The fluidic layer is then ejected from the mold and finished in a secondary machining process.

The fluidic layer design guidelines ensure:

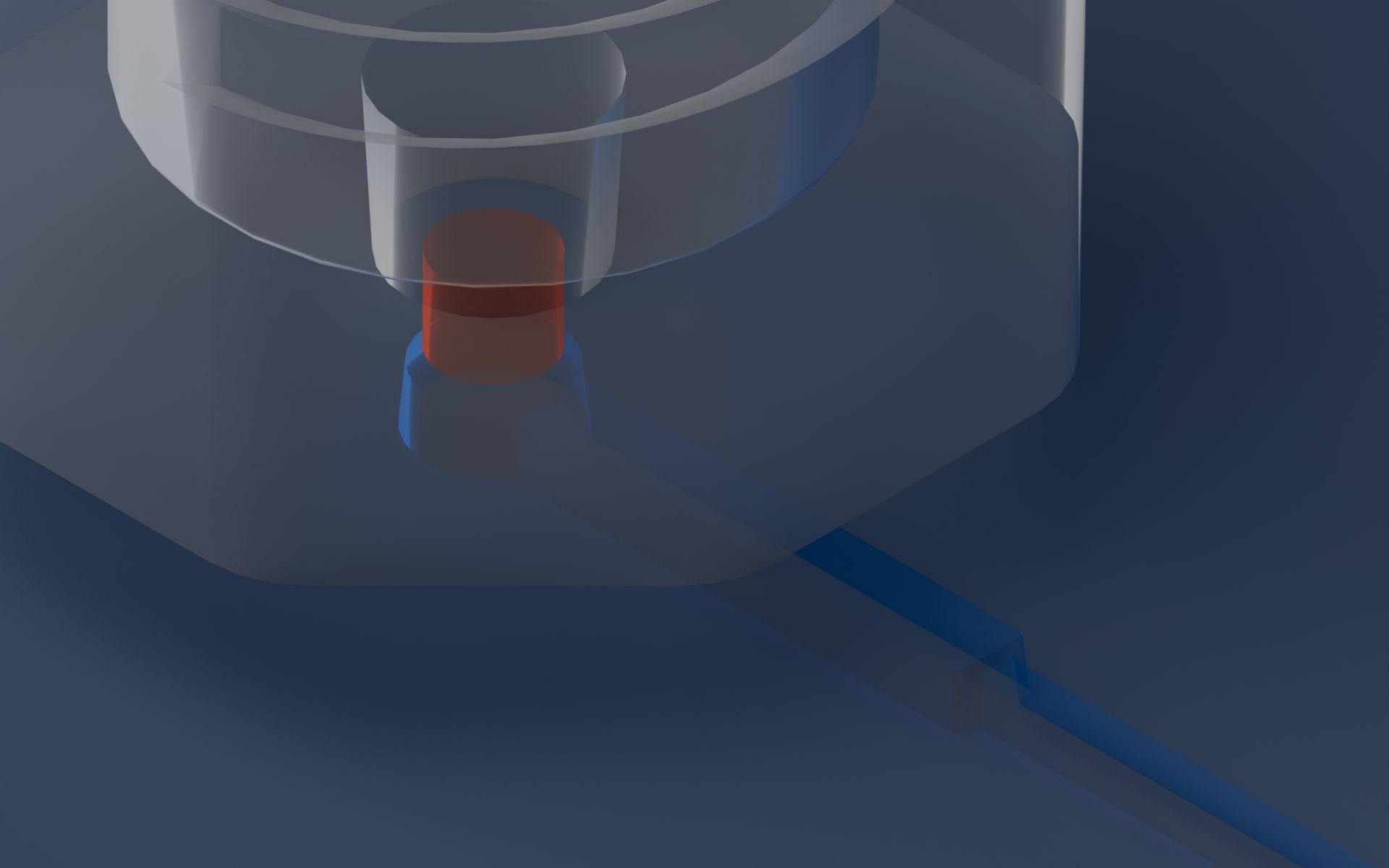

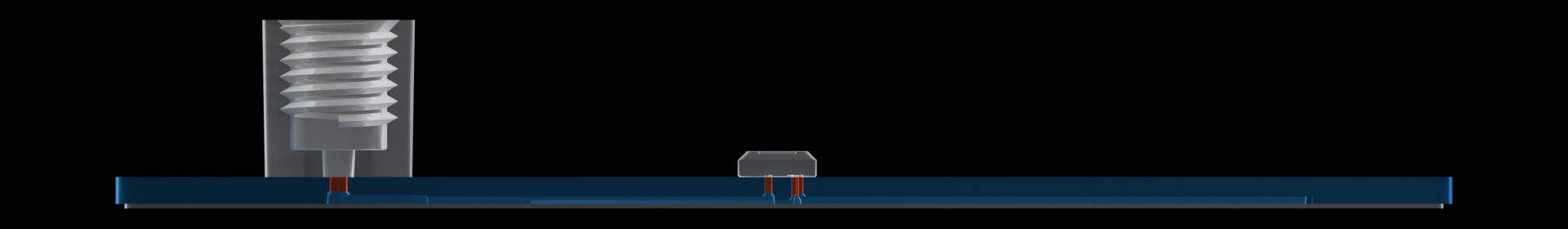

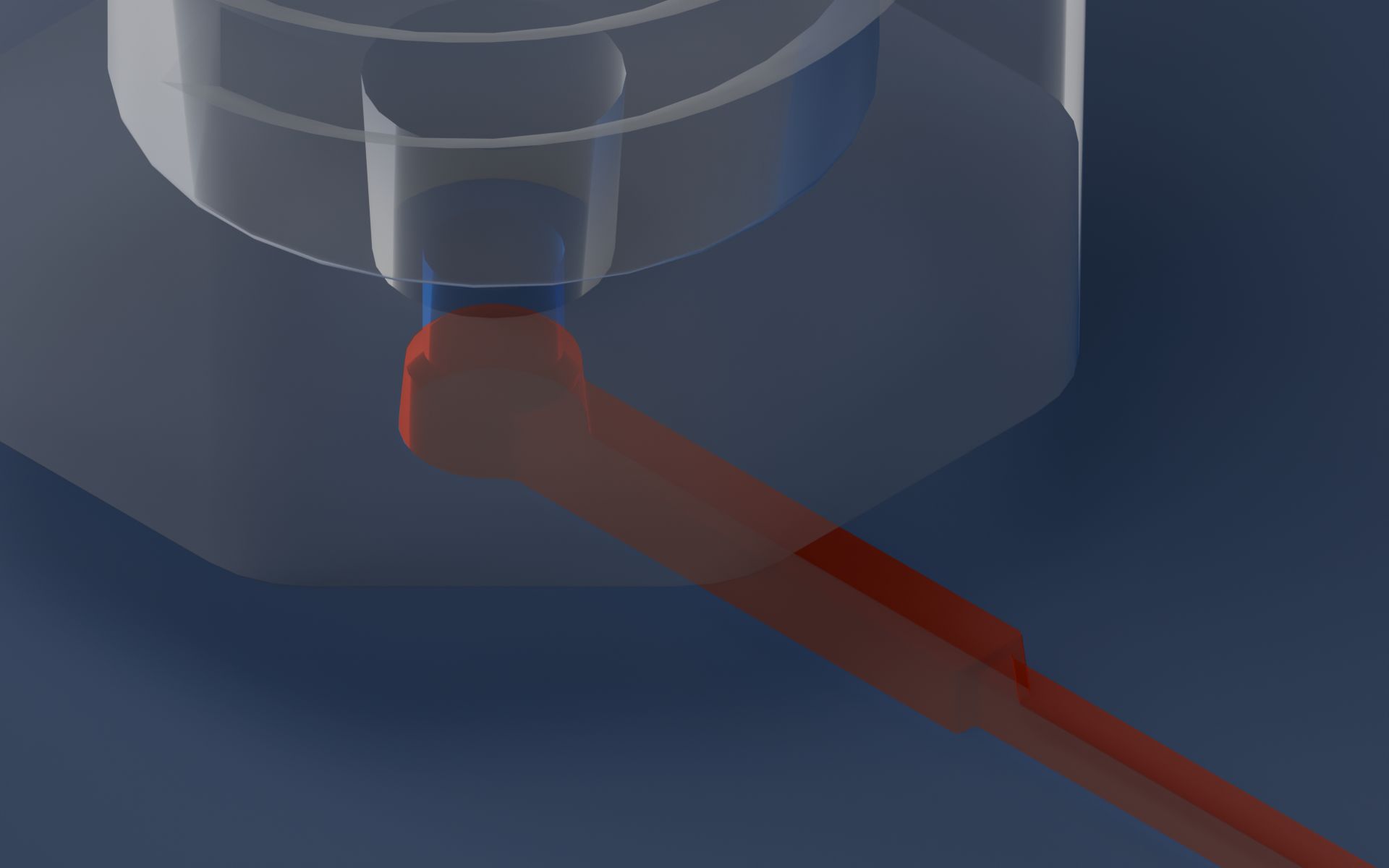

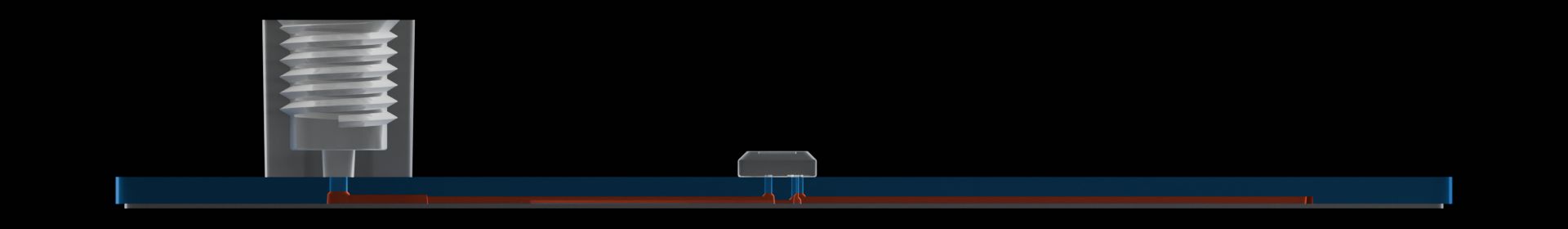

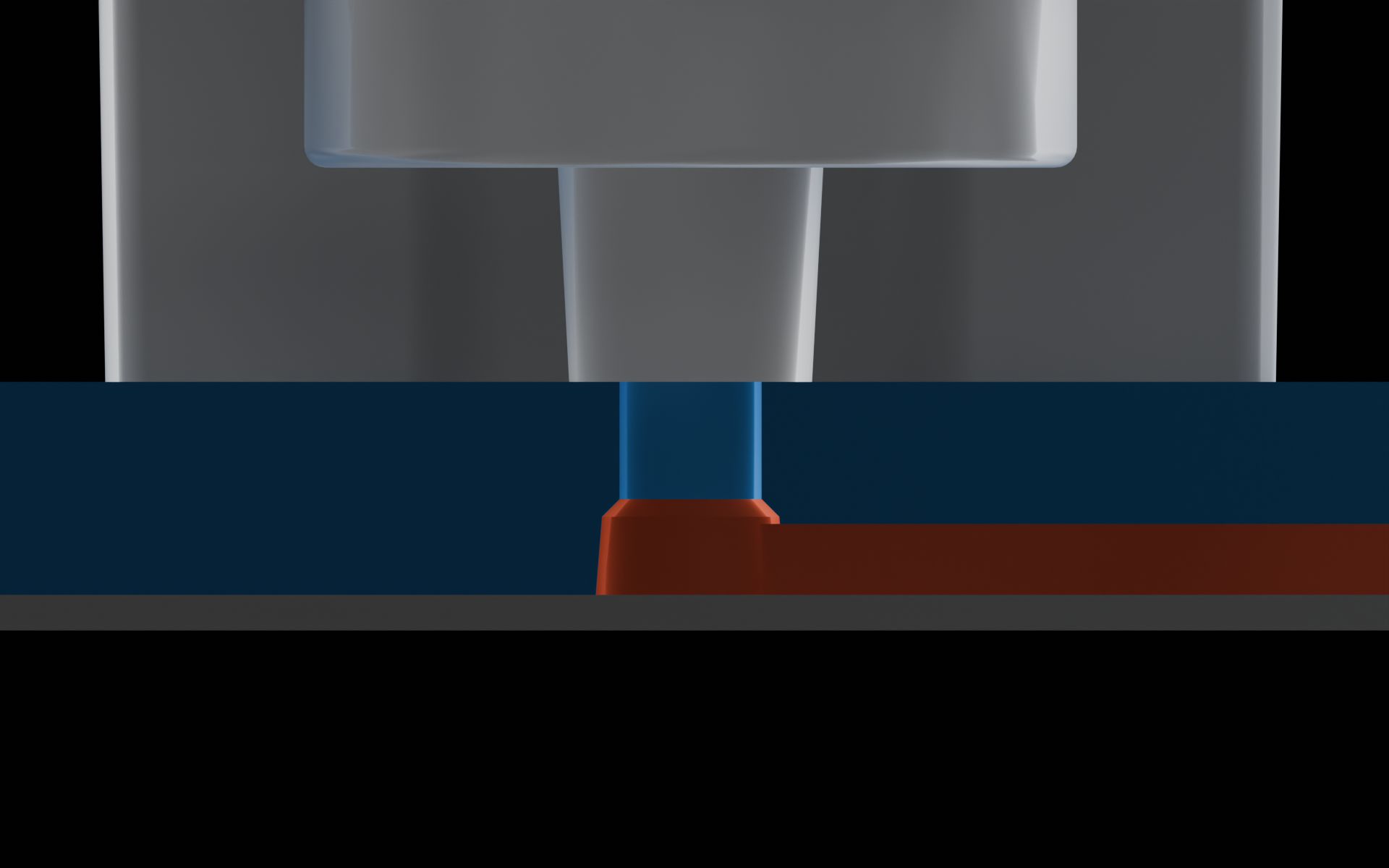

Molded microfeatures originate from the bottom side of the fluidic layer. They are replicated from the aluminum mold into the fluidic layer during the Transition Molding process.

Machined microfeatures originate from the top side of the fluidic layer. They are milled or drilled after the Transition Molding process in a secondary machining process.