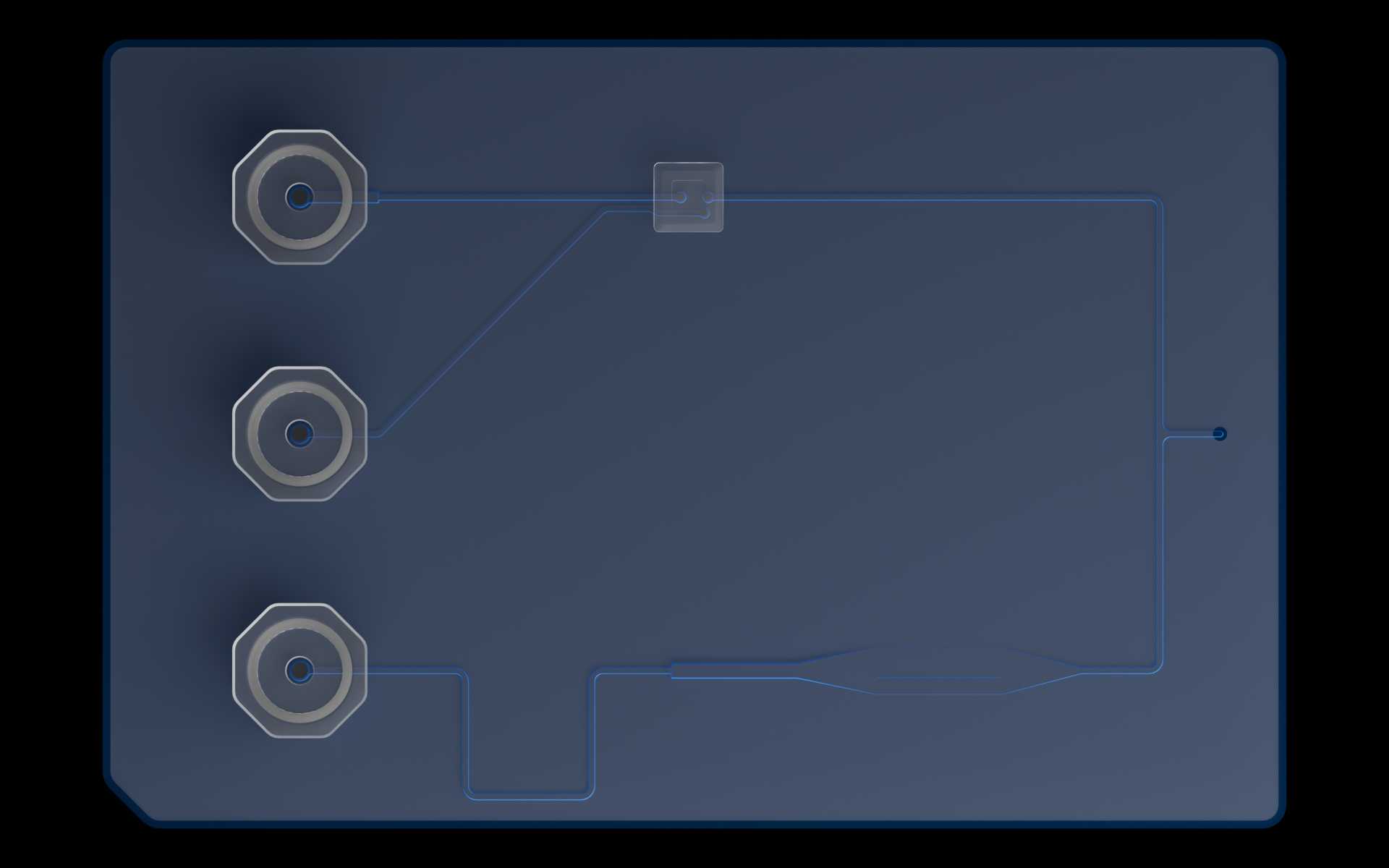

Vias

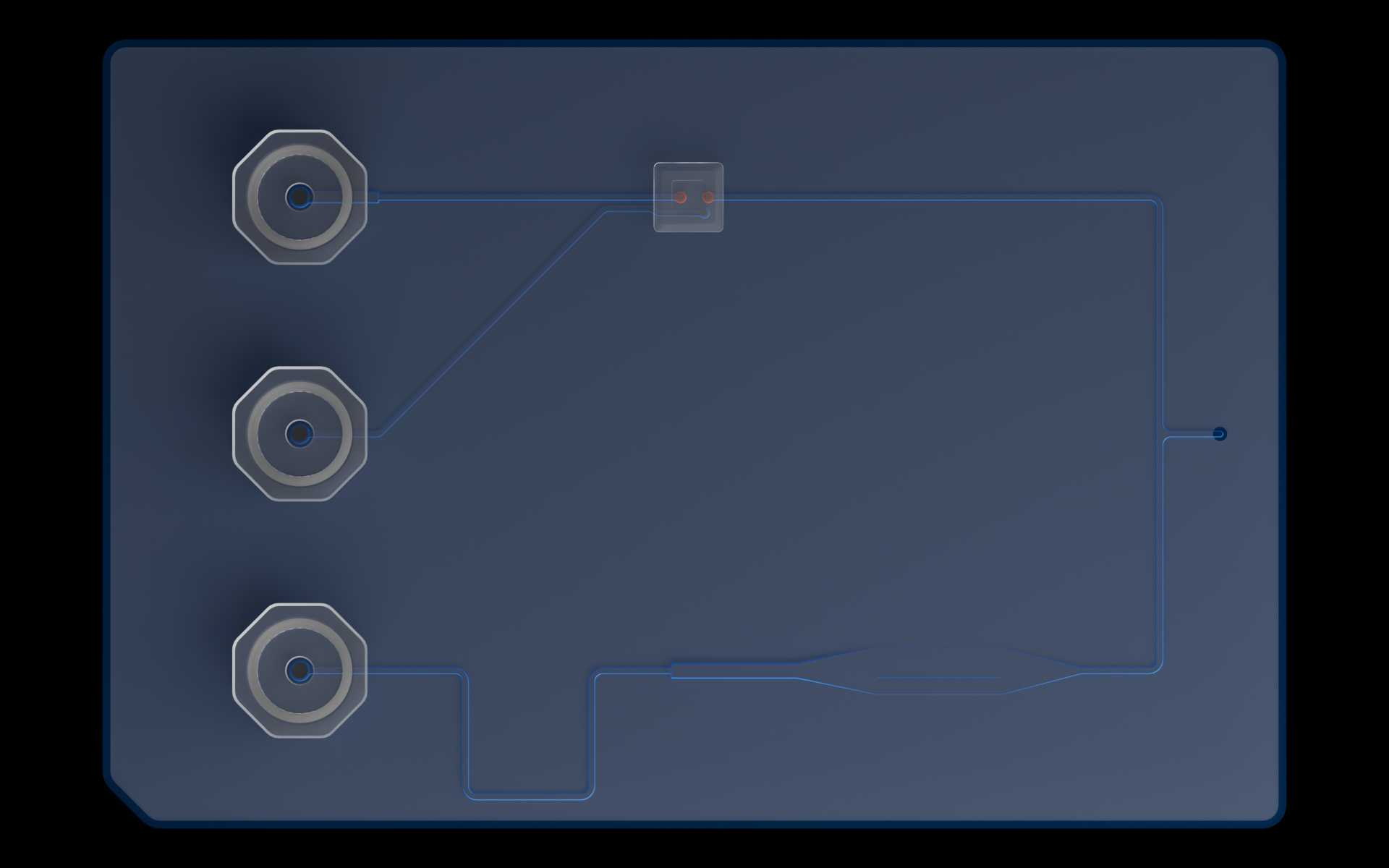

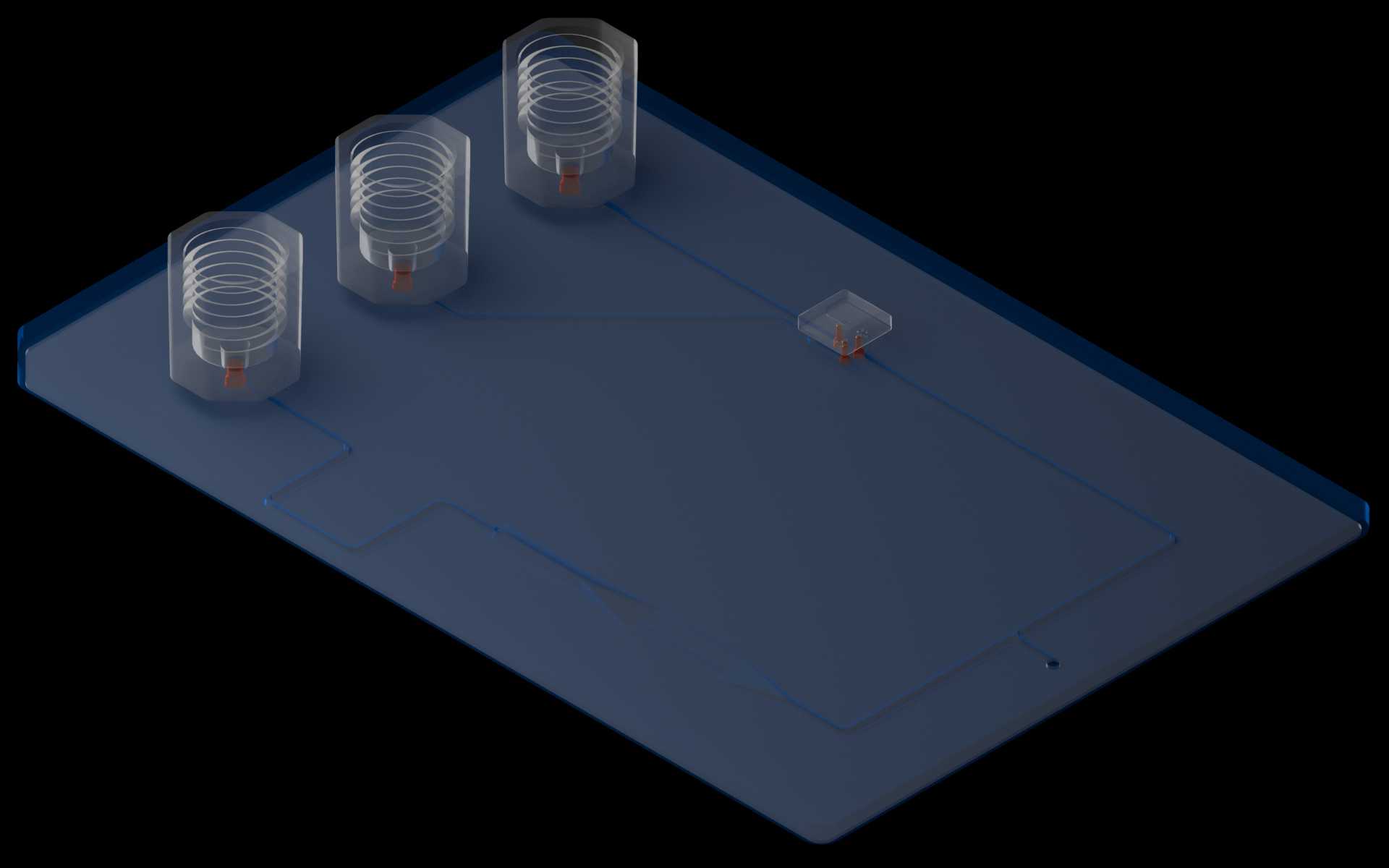

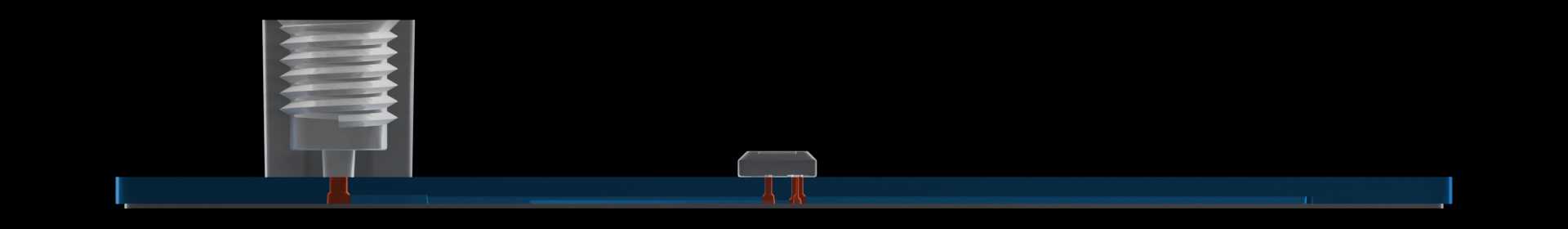

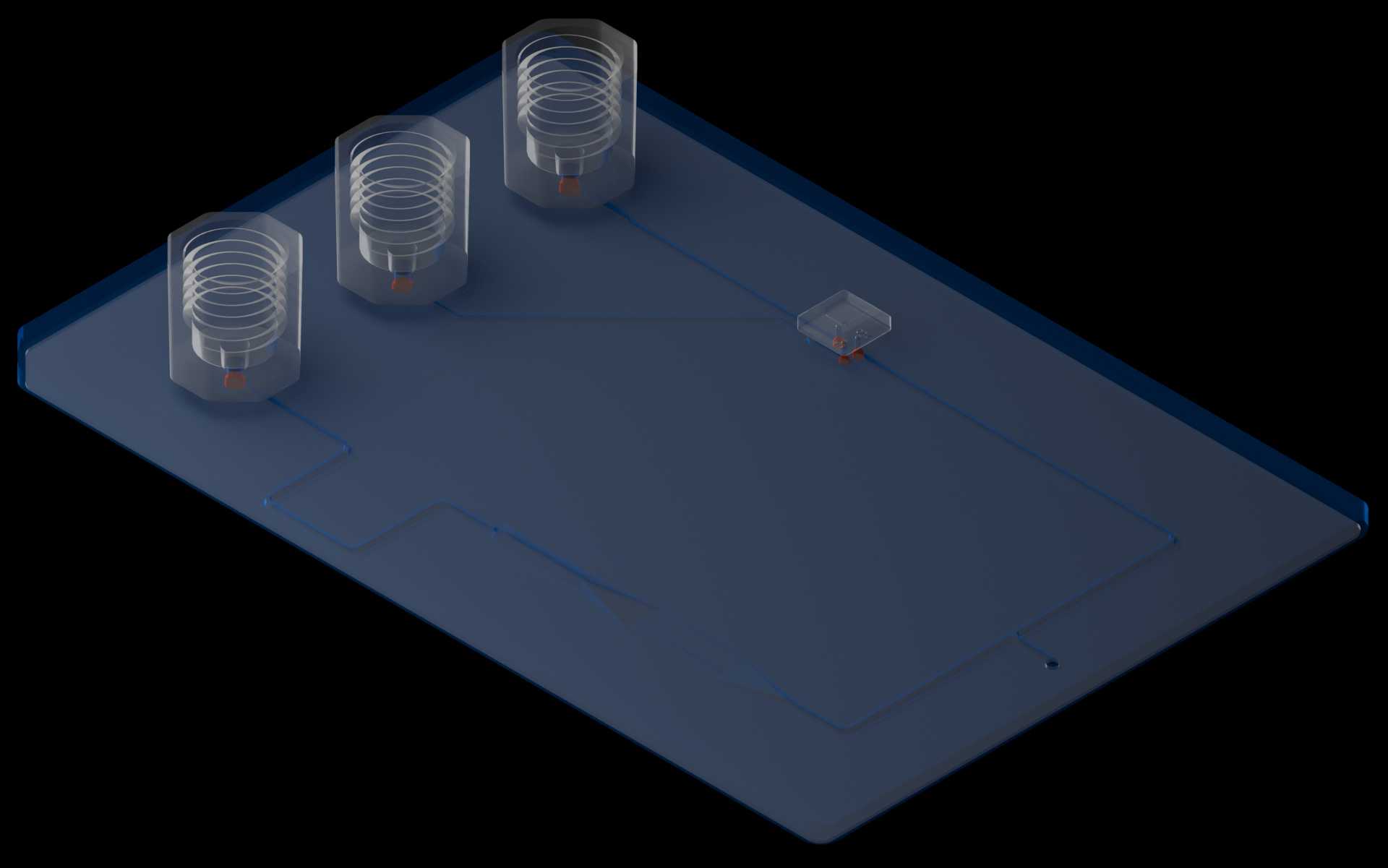

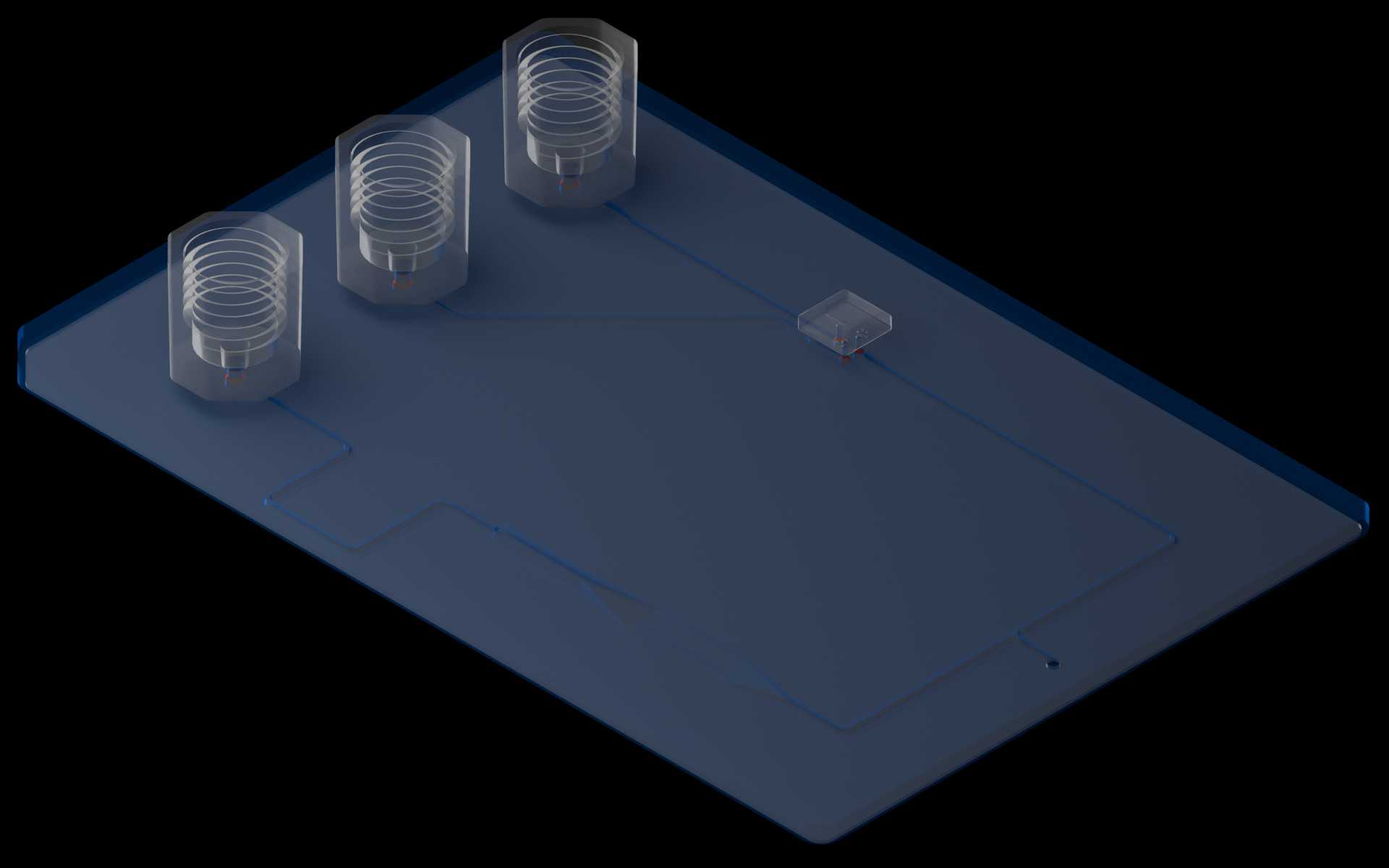

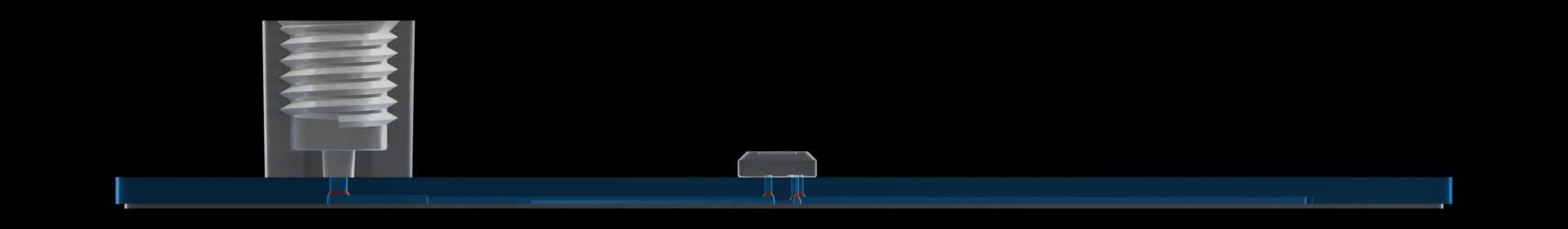

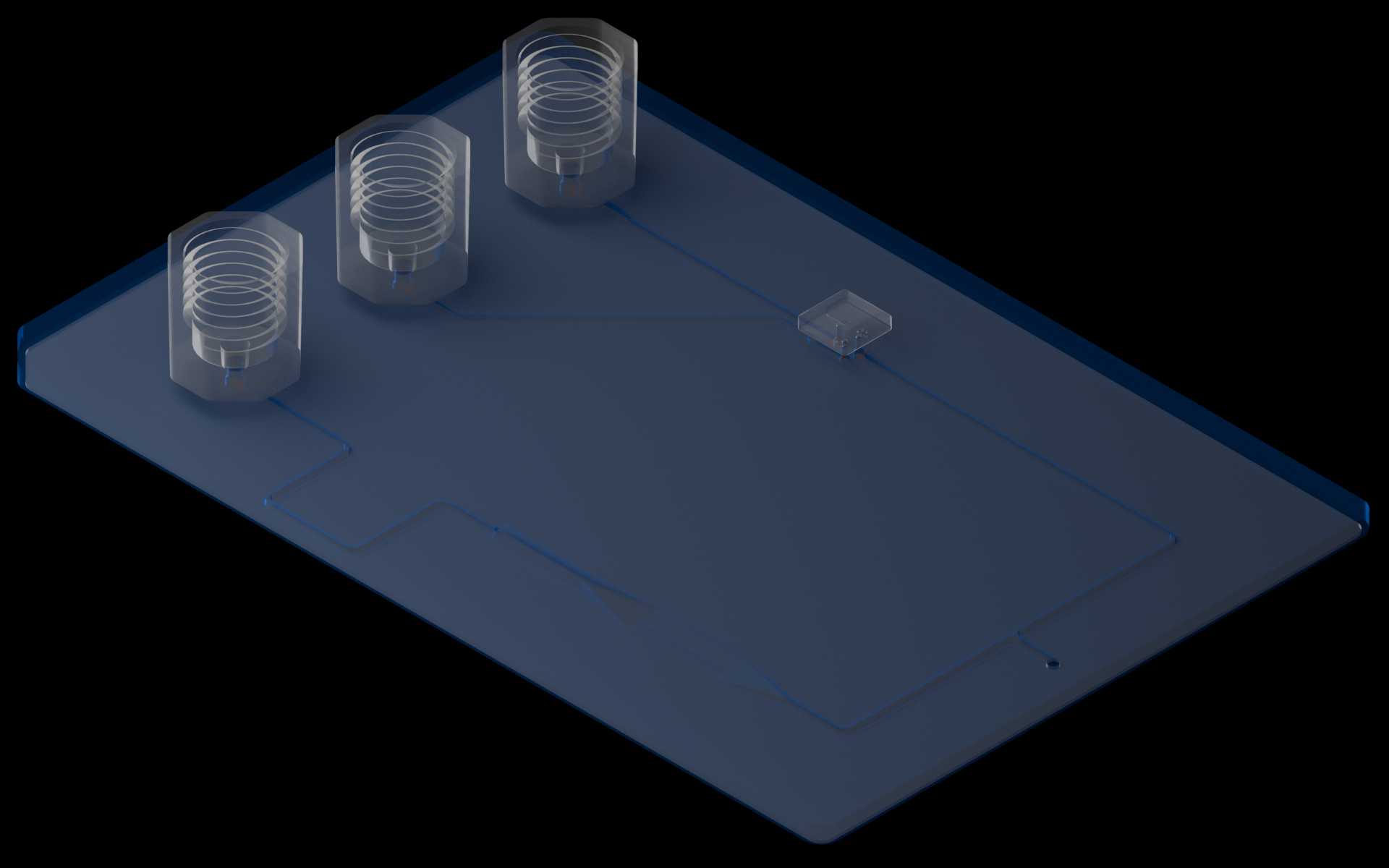

Part of Fluidic Layer

Part of Fluidic Layer

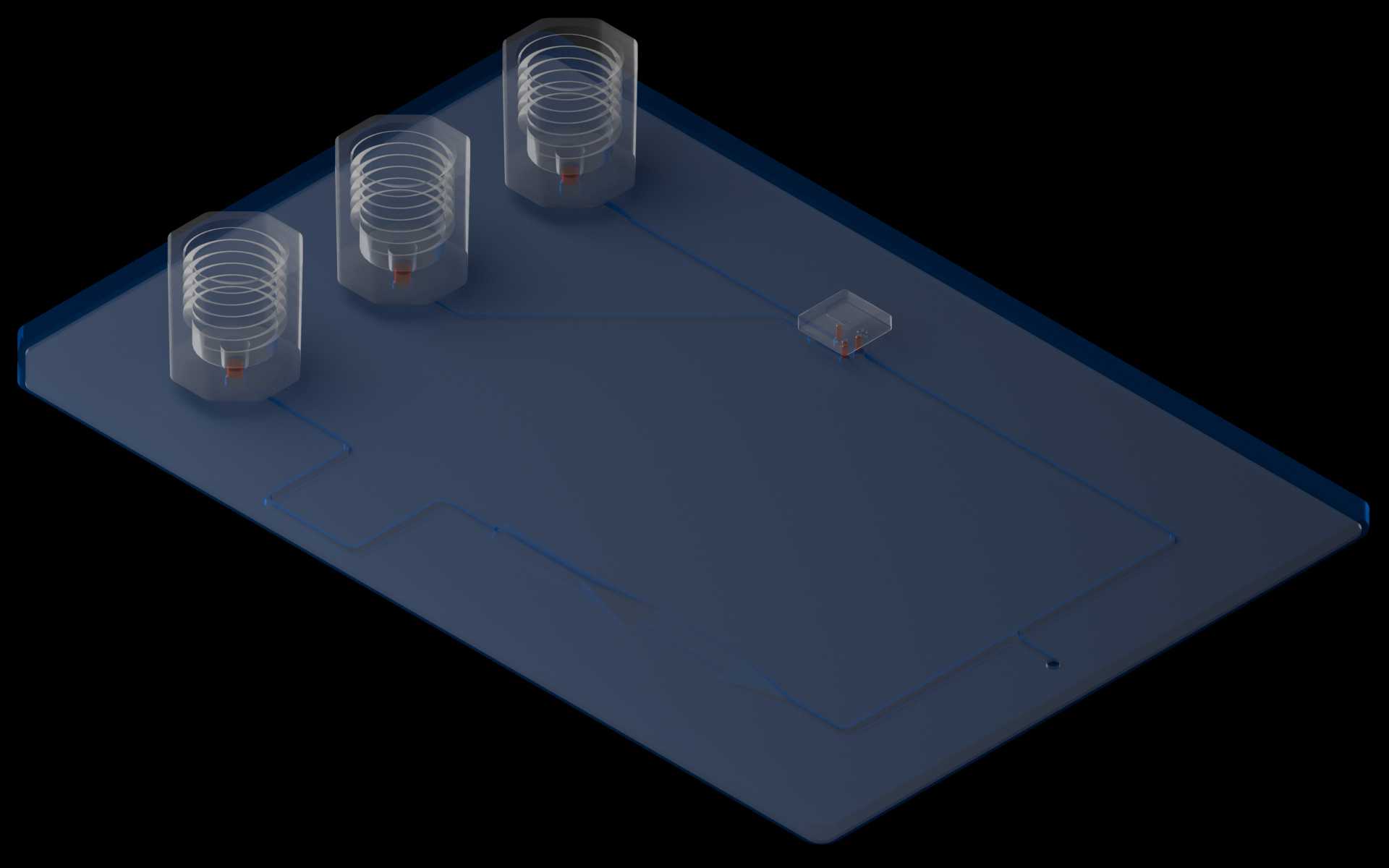

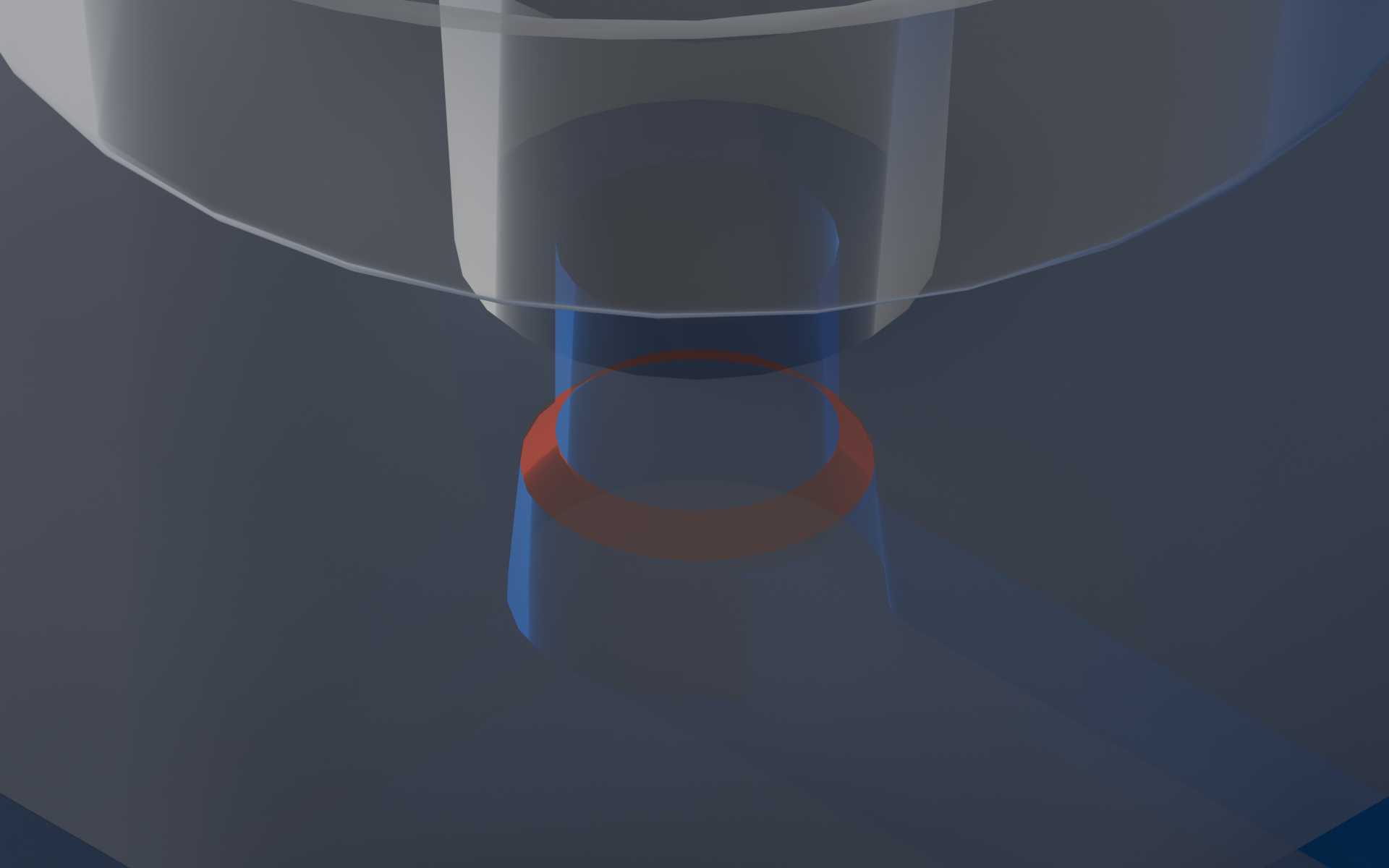

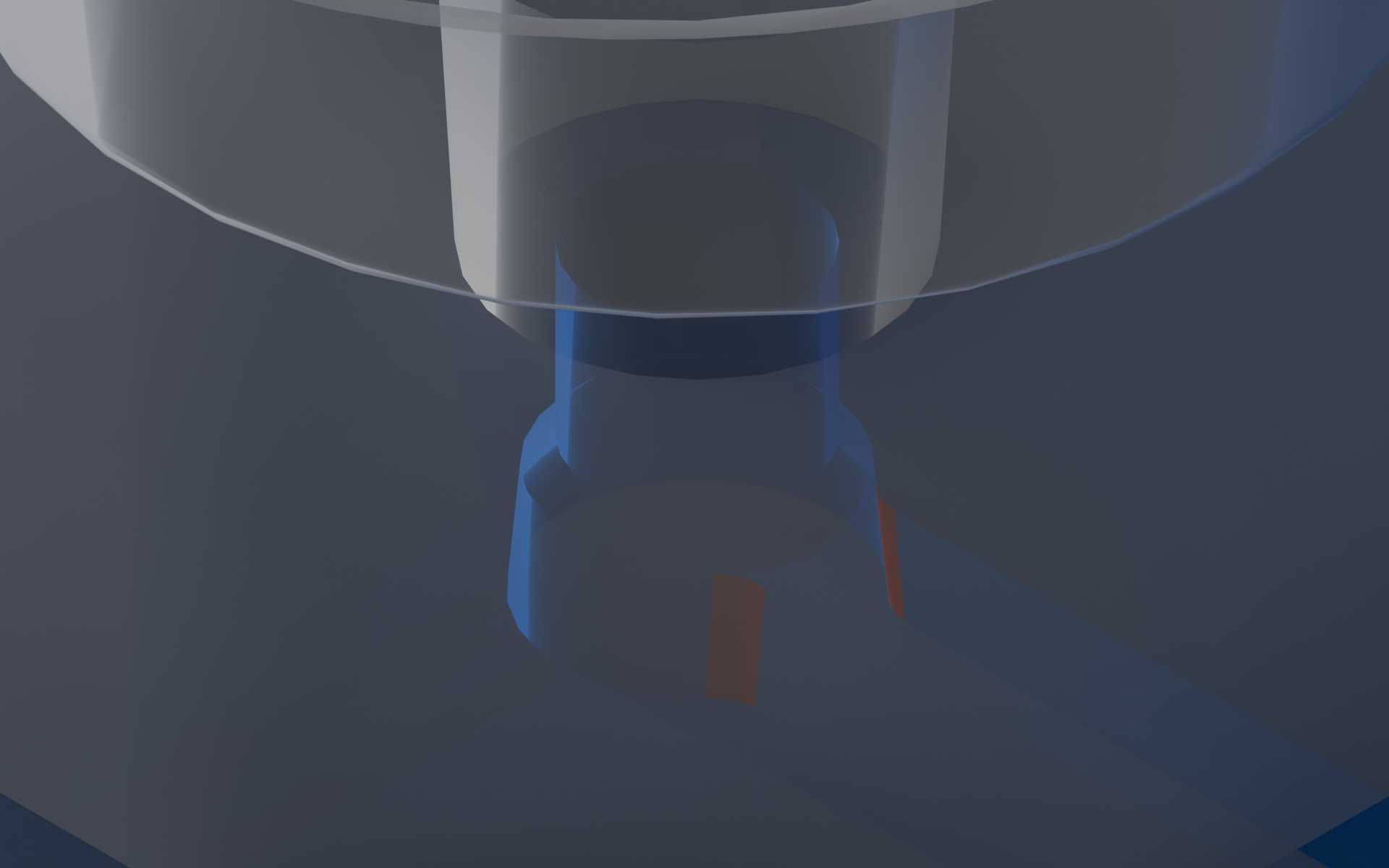

The connection between molded microfeatures and Parallel Hardware.

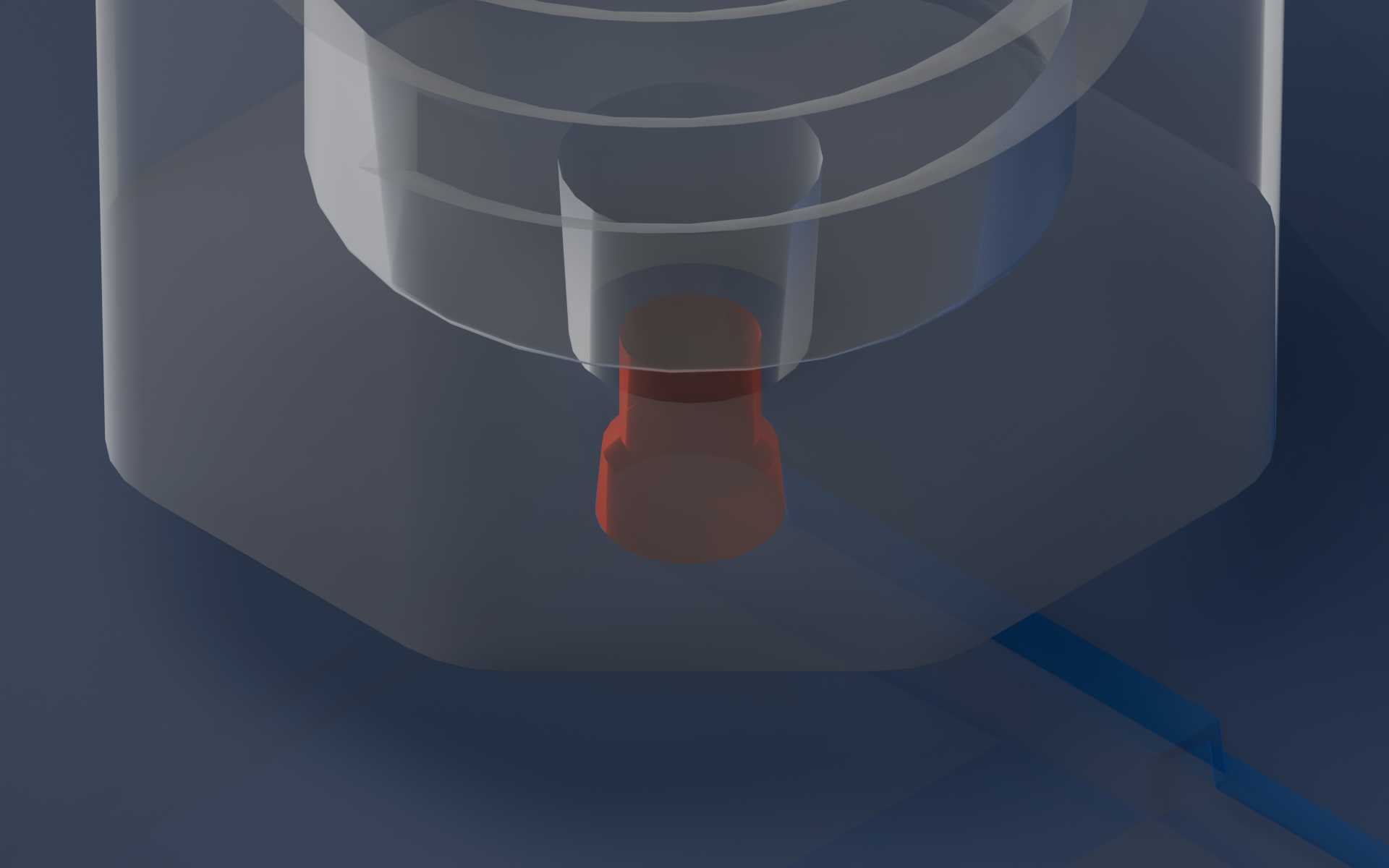

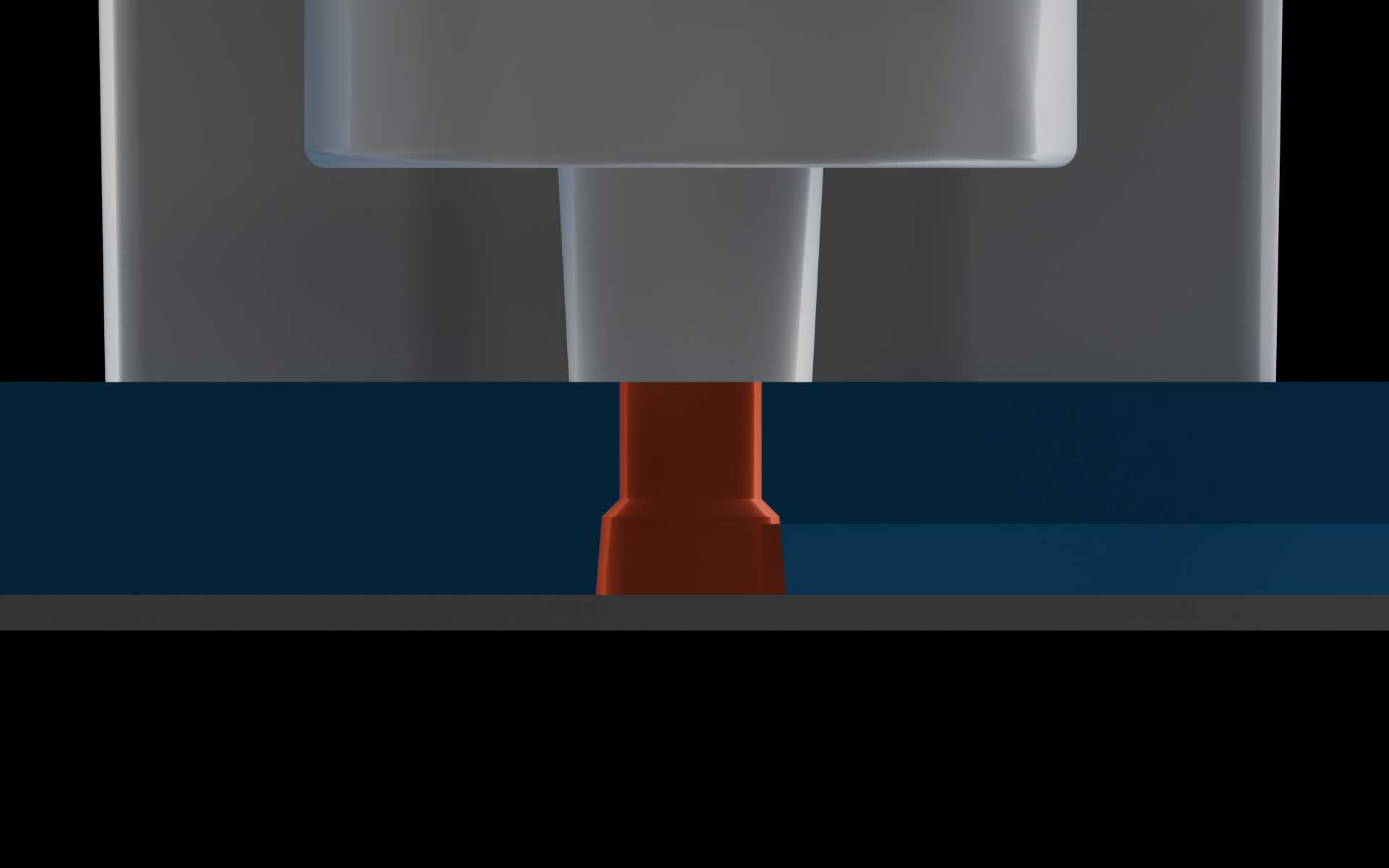

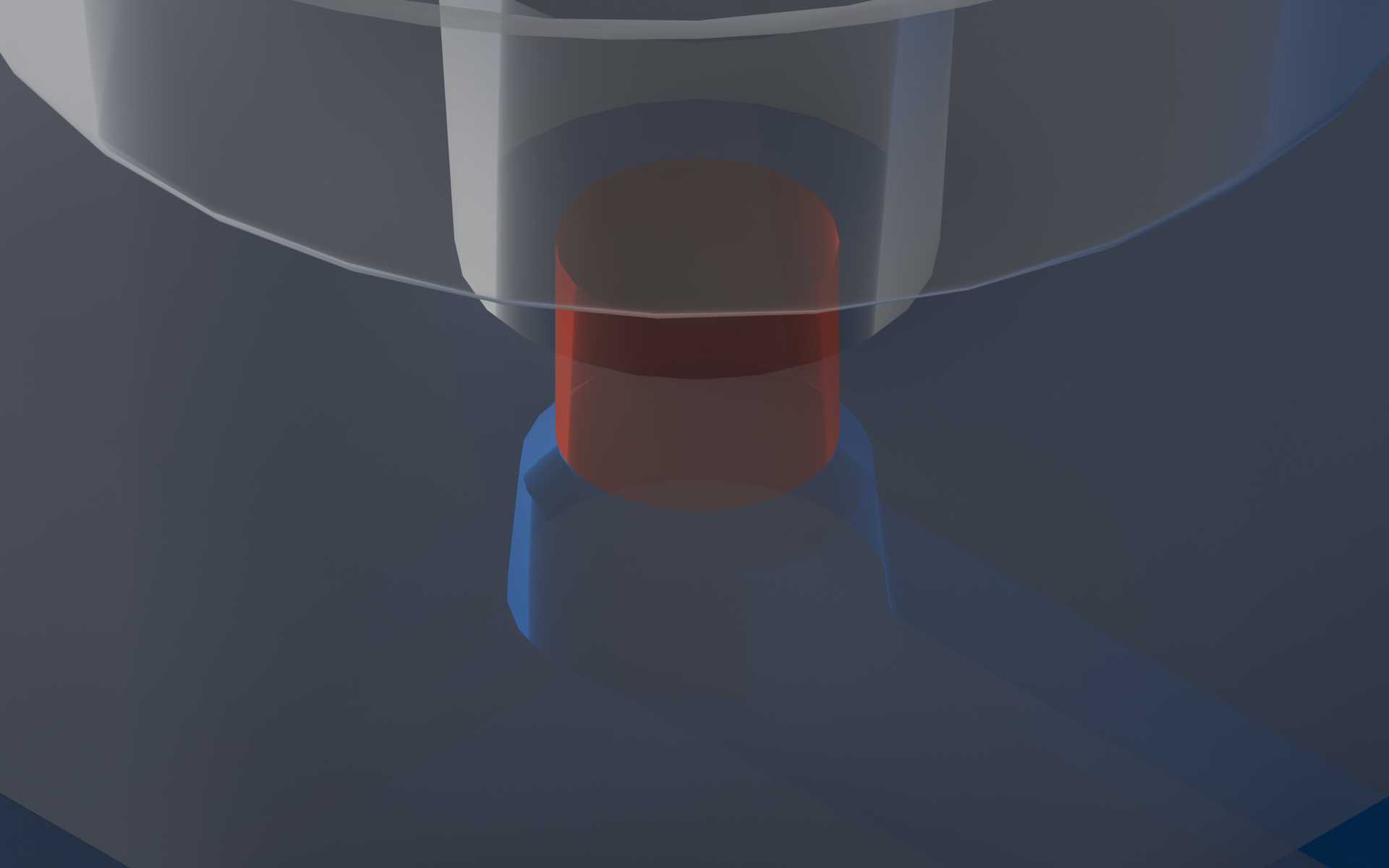

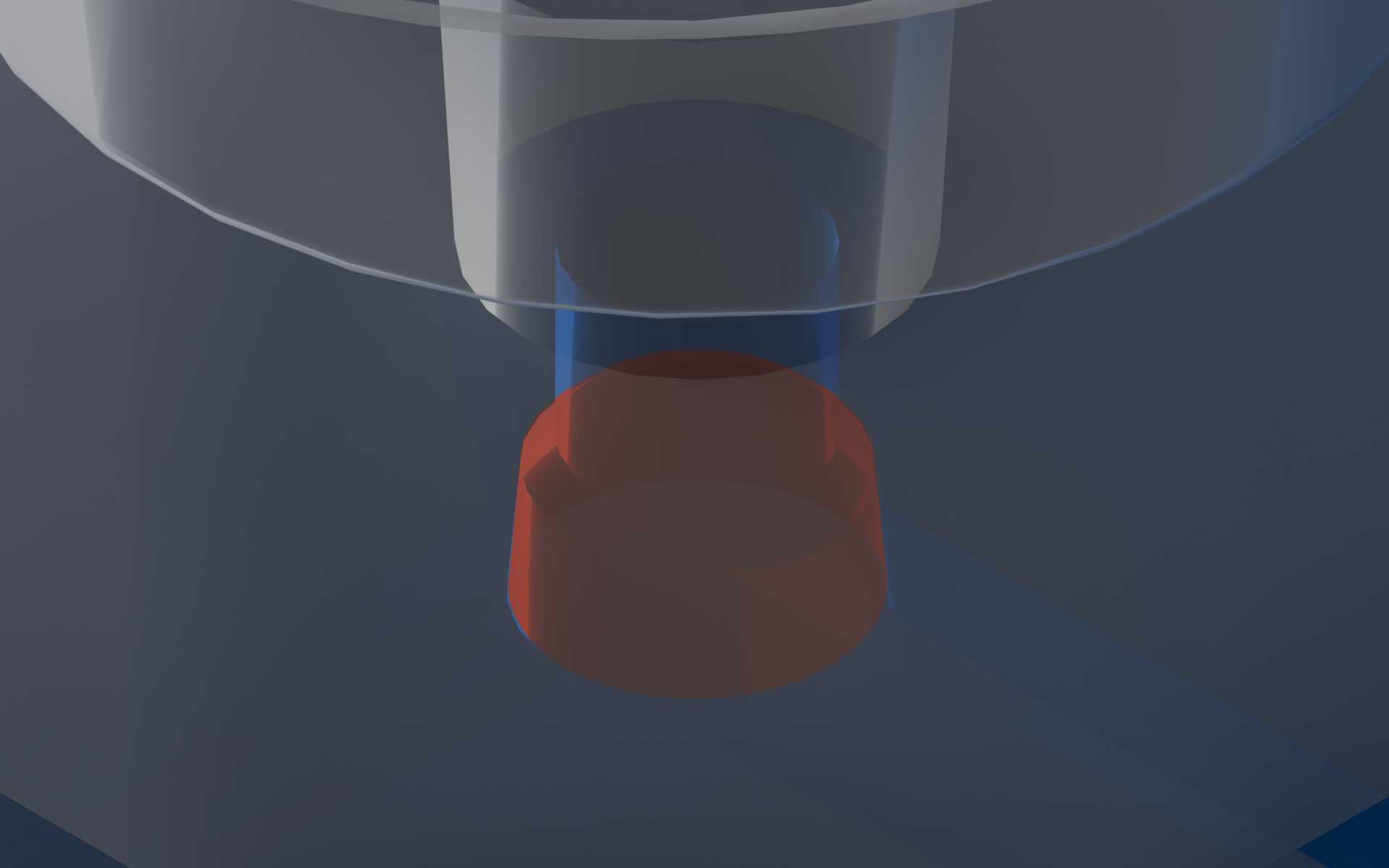

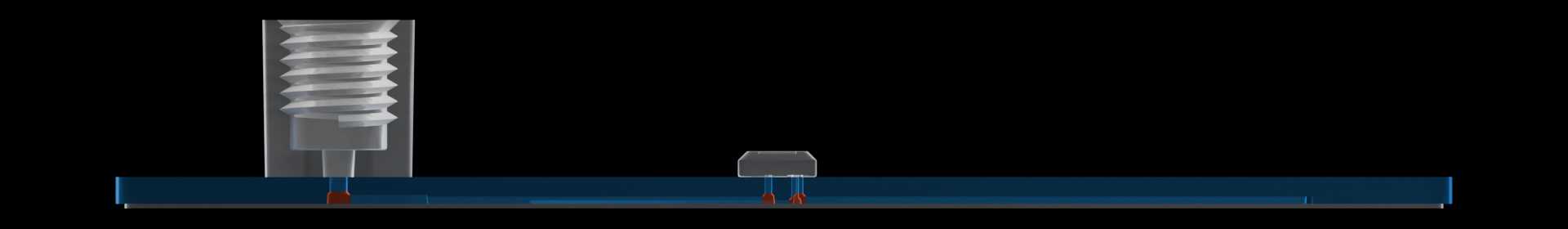

Vias go through the fluidic layer, creating connections to hardware. The top portion of a via is a machined microfeature while the bottom portion is a molded microfeature with a chamfer. The suggested design reduces the risk of defects and misalignment.

The dimensions for via spacing and sizing depend on the type of hardware used. Please reference the specific hardware for details.

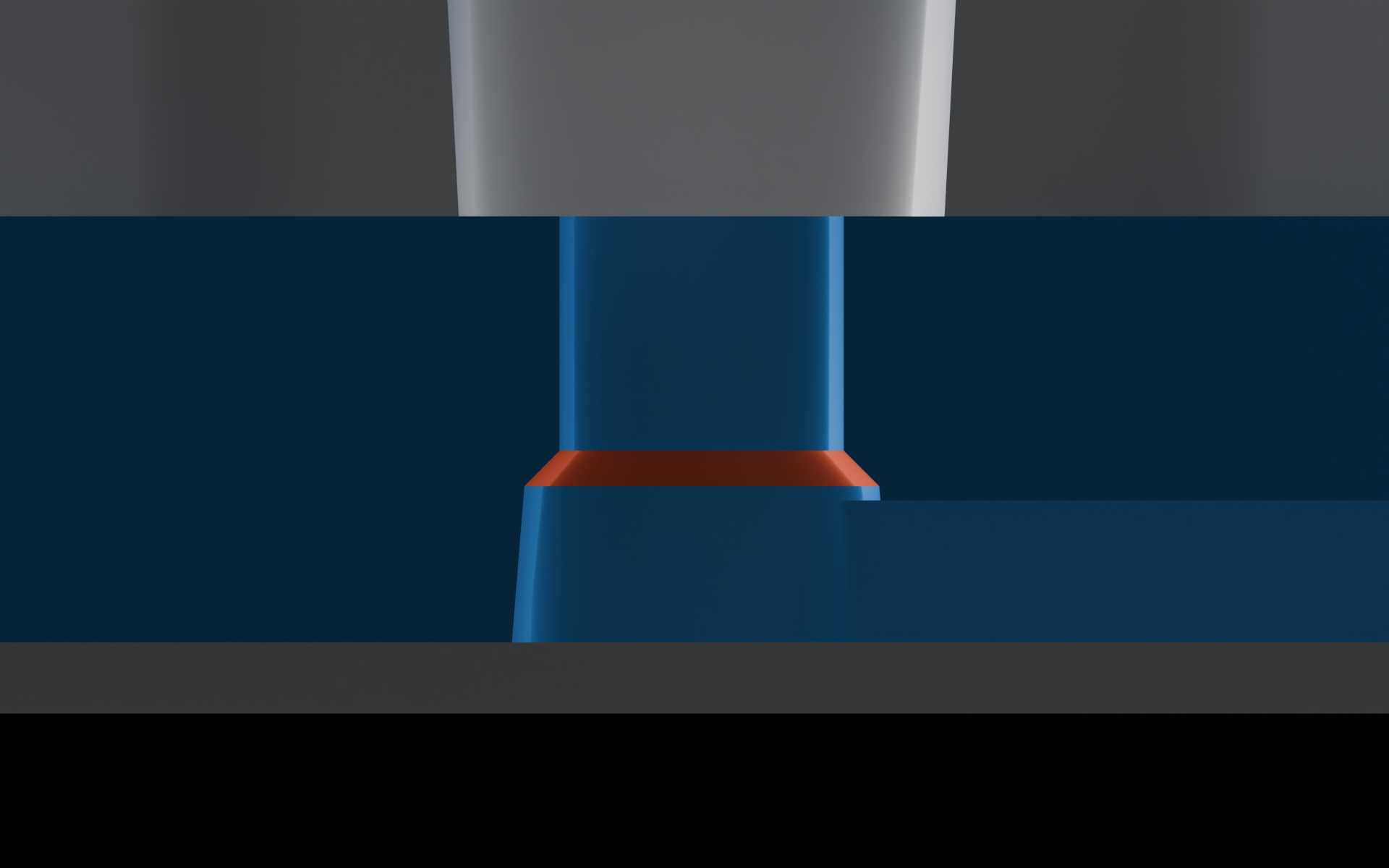

The machined portion of the via is a straight-walled hole drilled or milled into the top surface of the fluidic layer.

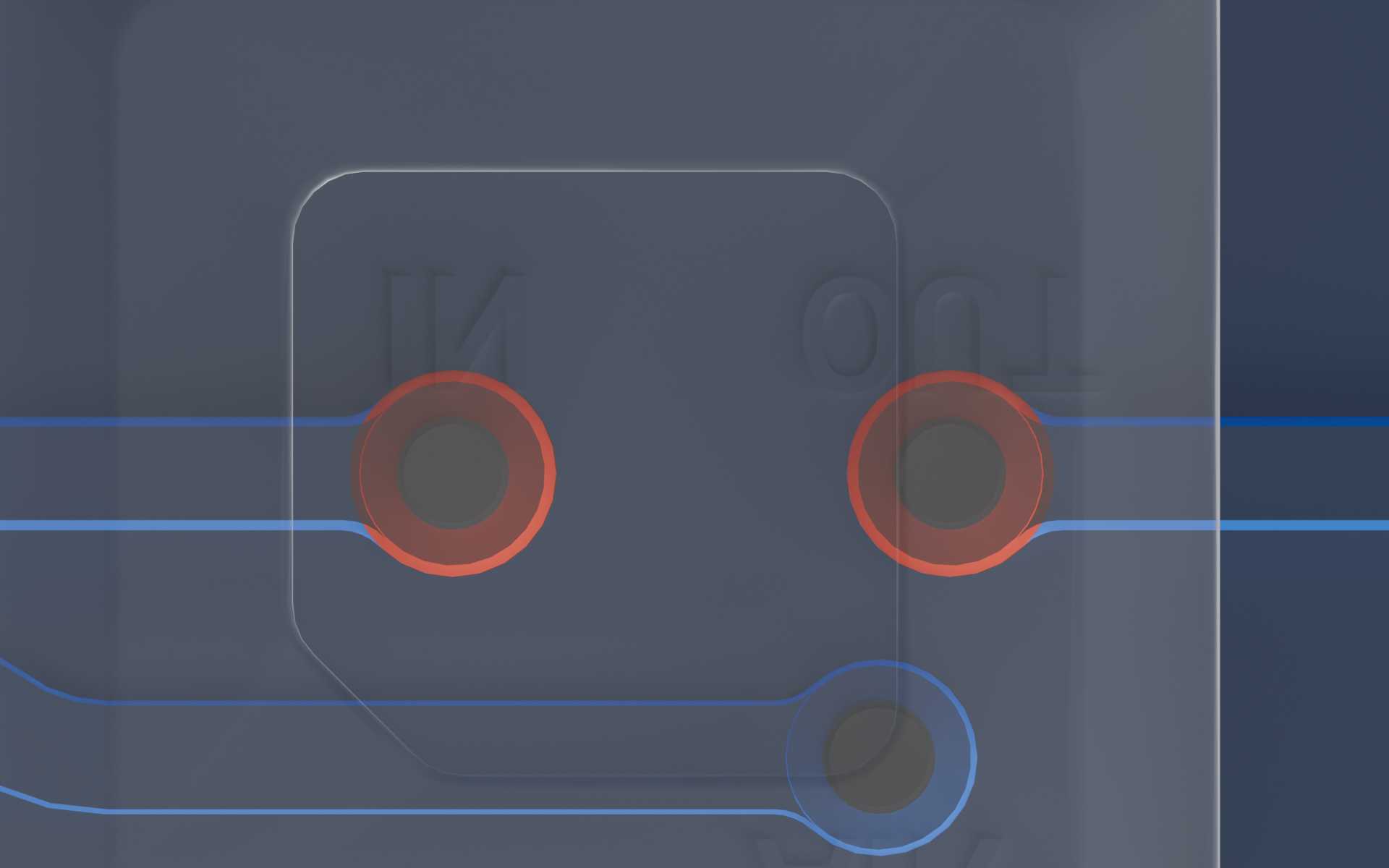

The molded portion of the via may be a standalone molded microfeature or part of a larger molded microfeature. In either case, it should follow molded microfeature dimensions and have a 5° draft. A chamfer creates a clean connection between the machined and molded portions.

The molded portion of the via should have a chamfer to mate with the machined portion. The chamfer should have a length of 125 µm, angled at 45°. The bottom edge of the chamfer should be 50 µm above the top surface of the connecting molded microfeature.

The corners where the via meets the connecting molded microfeature must have a corner radii of 200 µm.

Vias must be a