Microfluidic Devices, Fast

Custom devices in 3 days. Upload a design now to quote.

Custom devices in 3 days. Upload a design now to quote.

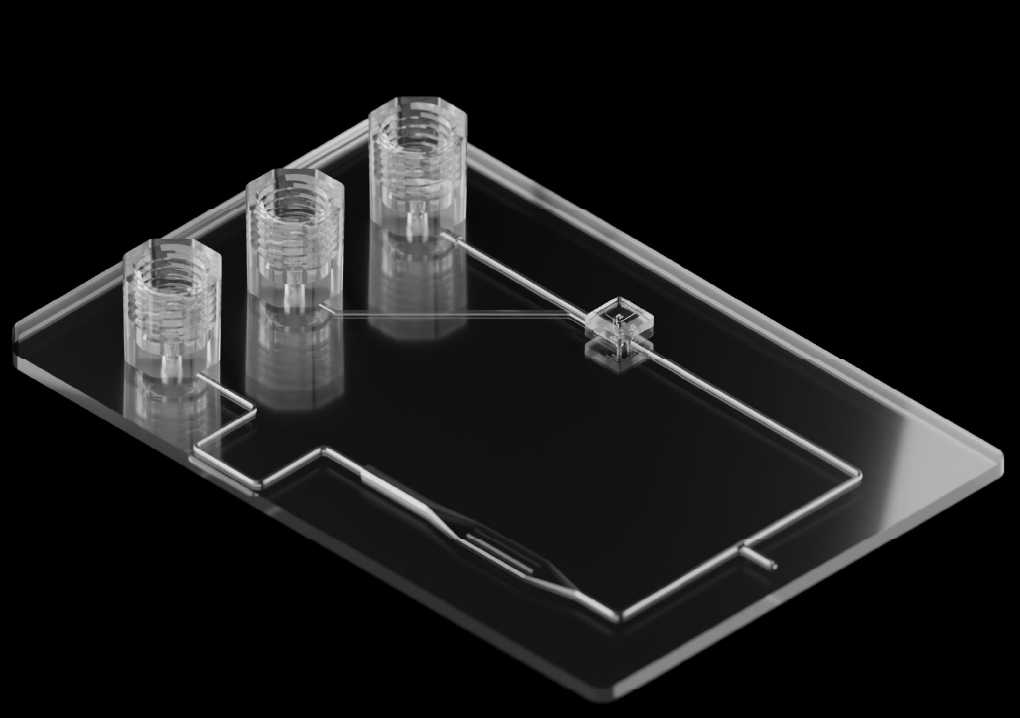

Build your device in production-grade materials from day one.

Shorten your development cycle with 10X faster iterations than legacy manufacturing.

Achieve molded part performance in a fraction of the time with Transition Molding.

Your real technology is what’s happening inside your chip. Embedded Hardware lets you prioritize your scientific challenges instead of reinventing the wheel to control or connect to flow.

Ramp up from a few prototype devices to hundreds per month with a single click. Dynamic quotes let you turn production on and off to meet your needs without lengthy and expensive contracts.

Device performance can vary wildly when switching from one material to another. With Transition Molding, you start with production-grade resins from day one, eliminating risk and shortening the time to scale up.

Follow our Design Guide to create your custom device.

Design GuideUpload your CAD file to generate a quote for your custom device.

Upload CADGet devices manufactured in as few as 3 days.

Manufacturing Process

Parallel Fluidics went above and beyond in helping us fabricate our chip. The turnaround time was incredibly fast, and the quality exceeded our expectations—truly unlike anything we've seen before.

Anonymous Aerospace Engineer

Parallel Fluidics enabled our rapid prototyping for a critical blood testing cartridge, delivering flexible design support that helped us quickly iterate and identify a successful flow channel configuration. Their fast turnaround and technical expertise allowed us to efficiently advance toward high-volume injection molding.

Natalya Mizrahi Director of Biomedical Integration

We received the first ten [devices] this morning. The first reaction was "WOW, that is amazing for one week turn around!"

Brad Thomas Engineering Fellow

We were able to quickly iterate and investigate microfluidic designs. The fact that Parallel could produce prototypes for us using materials similar to our final production selection allowed us to de-risk our designs with respect to biocompatibility and biological behavior.

Hardeep Singh Lead Engineer

Working with the team at ParallelFluidics has been an absolute pleasure. They are friendly, knowledgeable, and consistently go above and beyond to support my work. They’ve helped me cut down the production time of my microfluidic sensors and have provided me with high-quality, durable devices that perform reliably. I especially value their flexibility in adapting to my needs, which has made them an outstanding partner in my research.

Alessandra Luna BME PhD Student

Parallel Fluidics has been a great partner for rapid manufacturing of our complex microfluidic designs. The ability to create prototypes from the same thermoplastics we intend to use in production is very beneficial in speeding up the design process.

Revi Pendse COO

Parallel Fluidics radically streamlined our microfluidic device prototyping. They have become a trusted partner thanks to their expert knowledge, fast turnaround times, and high quality standards.

Director at stealth biotech startup

Accelerate your microfluidic technology development.