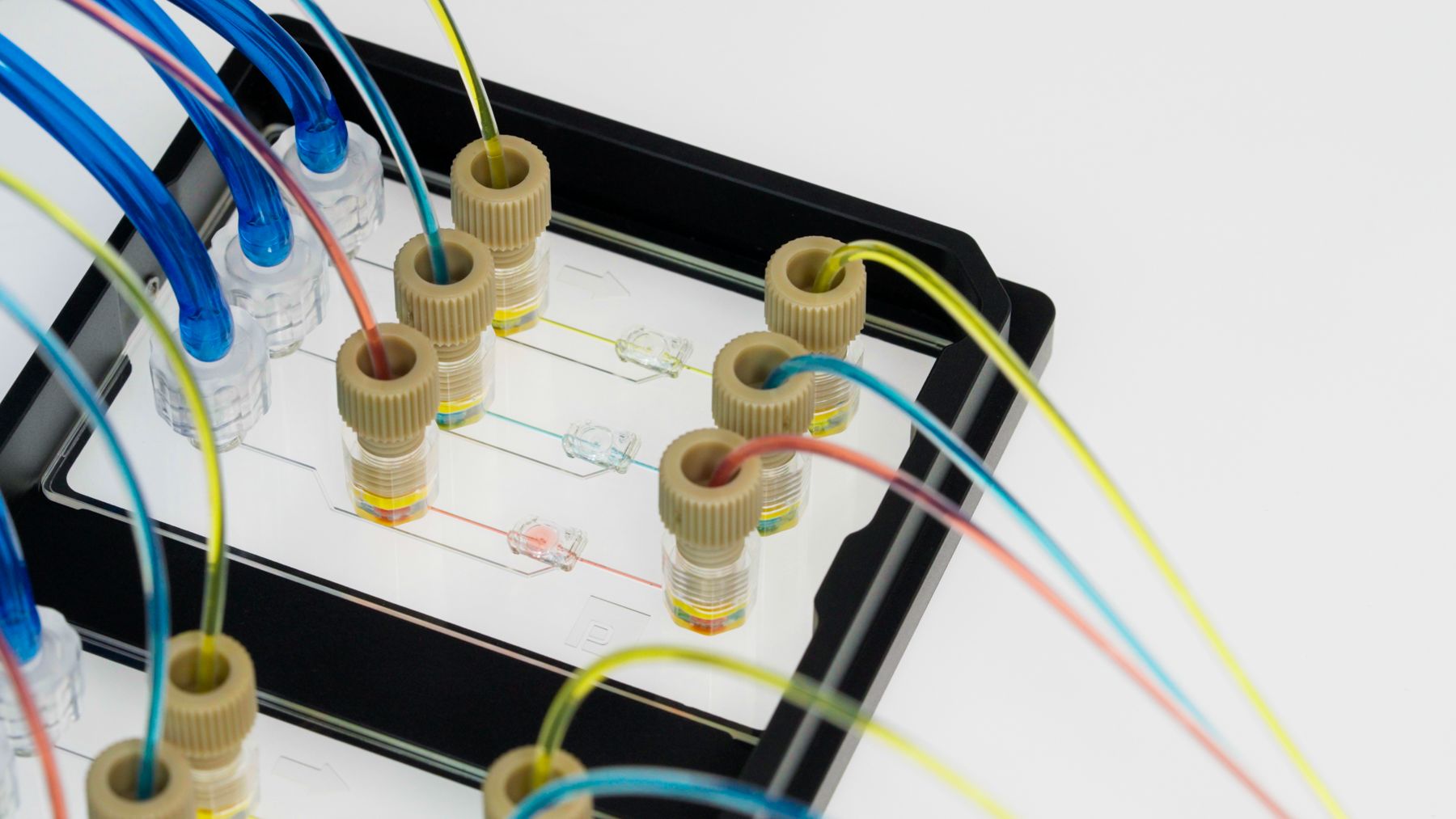

While creating flow and adding reagents in a microfluidic device sounds simple, it results in a tangle of tubes and fittings that inevitably leads to leaks and failures. Tubing-based systems may work for one-off studies on the lab bench, but they are impossible to integrate into an automated workflow.