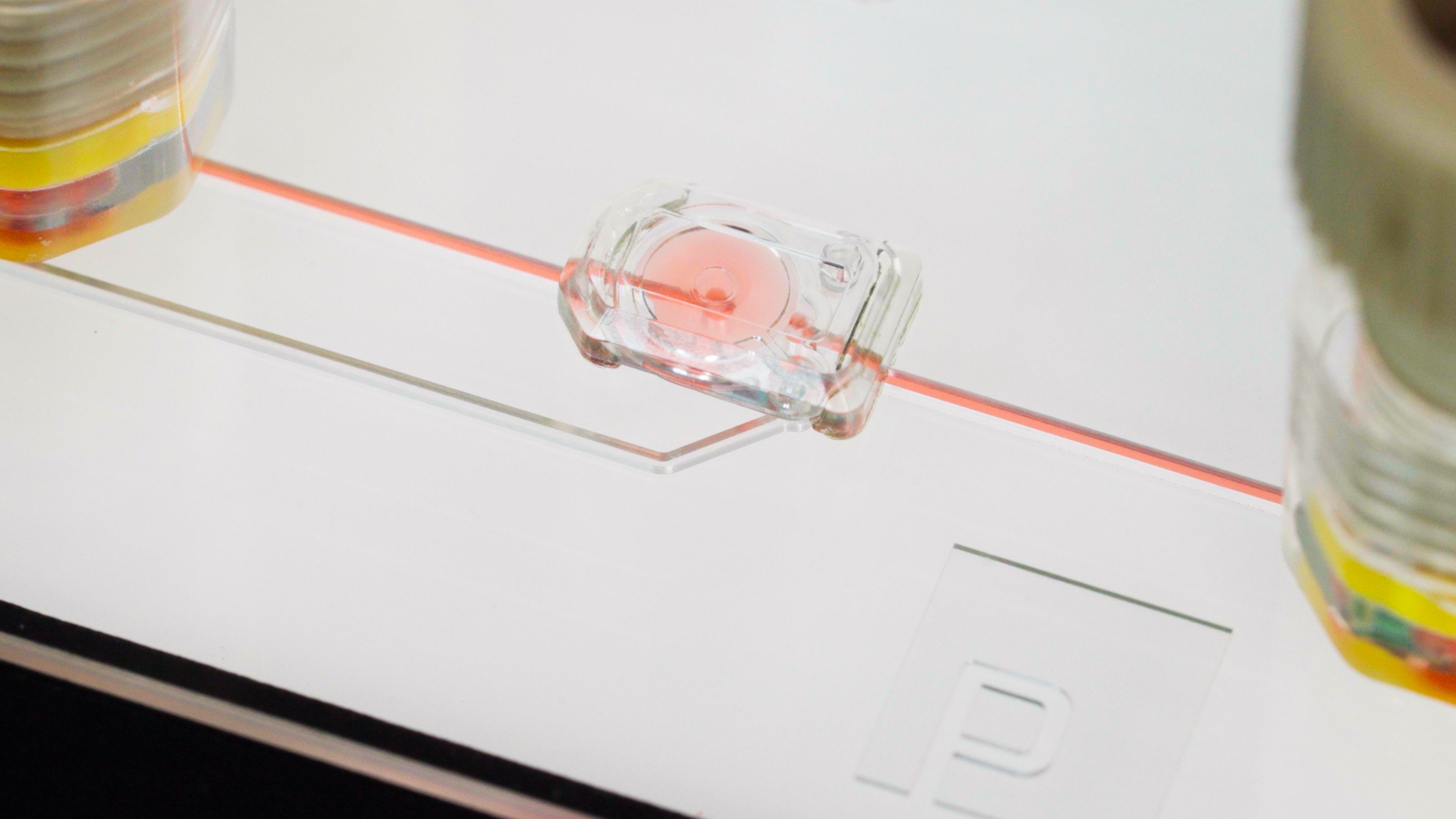

Flow control in microfluidic systems is always a challenge, especially for applications like point-of-care diagnostics that must be single-use, low-cost, and easy to operate. While existing options might work well for early R&D in the lab, they can be too expensive or unreliable for end-use devices.

-

External valves

Cumbersome tubing, requires a wash step between uses

-

Electronic valves

Too expensive for single-use, hard to integrate

-

Membrane valves

Difficult to manufacture, prone to failure